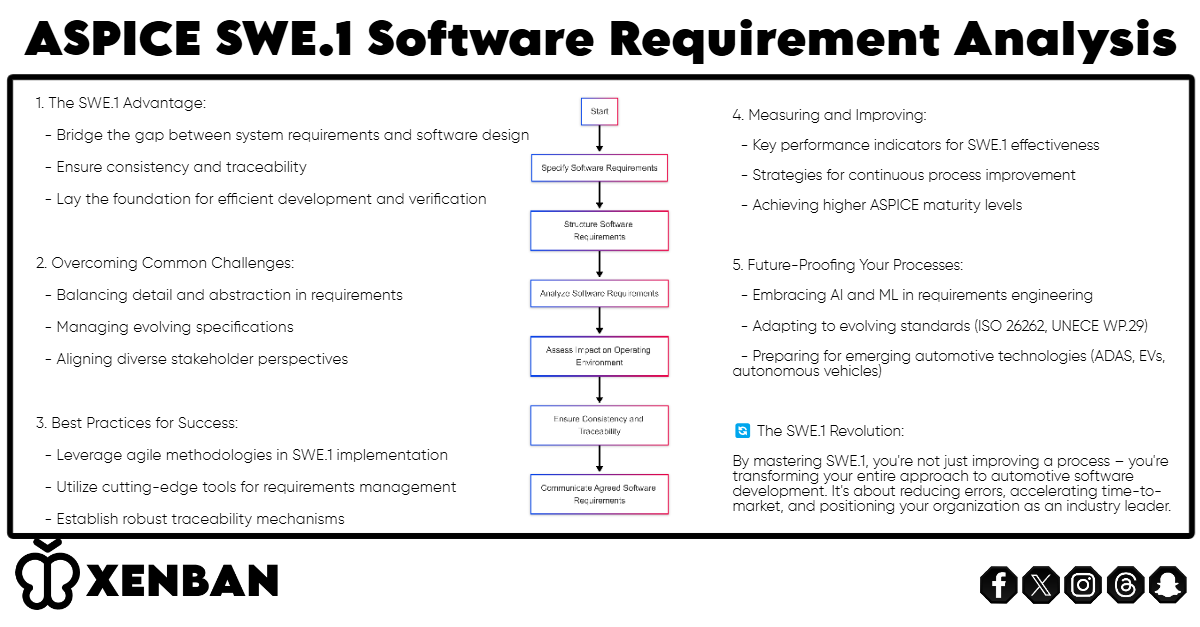

Executive Summary The Software Requirements Analysis (SWE.1) process is a cornerstone of Automotive SPICE (ASPICE), playing a crucial role in transforming system requirements into well-defined software requirements. This whitepaper delves into the intricacies of SWE.1, its significance in automotive software development, and best practices for implementation. As the automotive industry continues to evolve with increasingly complex software systems, mastering SWE.1 becomes paramount for organizations aiming to deliver high-quality, reliable, and compliant software solutions. 1. Introduction to ASPICE and SWE.1 1.1 Overview of Automotive SPICE Automotive SPICE (ASPICE) is a framework for assessing and improving software development processes in the automotive industry. It is based on the ISO/IEC 15504 standard and has been tailored to meet the specific needs of automotive software development. ASPICE provides a structured approach to process improvement, enabling organizations to enhance their software development capabilities and meet the stringent quality requirements of the automotive sector. 1.2 The role of SWE.1 in the software development lifecycle The Software Requirements Analysis (SWE.1) process is a critical component of ASPICE, focusing on the elicitation, analysis, and documentation of software requirements. It serves as a bridge between system requirements and software design, ensuring that all stakeholder needs are accurately captured and translated into implementable software specifications. 1.3 Key objectives and outcomes of SWE.1 The primary objectives of SWE.1 include: 2. The SWE.1 Process in Detail 2.1 Specifying software requirements The first step in SWE.1 involves eliciting and documenting software requirements based on system requirements and stakeholder needs. This process includes: 2.2 Structuring software requirements Once requirements are identified, they must be organized and structured to facilitate understanding and traceability. This involves: 2.3 Analyzing software requirements The analysis phase is crucial for ensuring the quality and feasibility of requirements. Key activities include: 2.4 Assessing impact on the operating environment Software requirements must be evaluated in the context of the target operating environment. This involves: 2.5 Ensuring consistency and traceability Maintaining consistency and traceability is essential for effective requirements management. This includes: 2.6 Communicating agreed software requirements Effective communication of software requirements is crucial for aligning all stakeholders. This involves: 3. Challenges in Implementing SWE.1 3.1 Common pitfalls in software requirements analysis Organizations often face several challenges when implementing SWE.1: 3.2 Balancing detail and abstraction Finding the right level of detail in software requirements is crucial. Too much detail can lead to over-specification and reduced flexibility, while too little detail can result in ambiguity and misinterpretation. 3.3 Managing changing requirements The dynamic nature of automotive projects often leads to changing requirements. Effective change management processes are essential to maintain consistency and traceability throughout the development lifecycle. 3.4 Ensuring stakeholder alignment Aligning diverse stakeholder perspectives and priorities can be challenging. Effective communication and negotiation skills are crucial for reaching consensus on software requirements. 4. Best Practices for SWE.1 Implementation 4.1 Leveraging agile methodologies in SWE.1 Integrating agile practices with SWE.1 can enhance flexibility and responsiveness to changing requirements. Key approaches include: 4.2 Tools and techniques for effective requirements management Utilizing appropriate tools and techniques can significantly improve the efficiency of SWE.1 implementation: 4.3 Establishing robust traceability mechanisms Implementing comprehensive traceability mechanisms is crucial for maintaining consistency and facilitating impact analysis: 4.4 Integrating SWE.1 with other ASPICE processes Effective integration of SWE.1 with other ASPICE processes is essential for overall process improvement: 5. Measuring Success in SWE.1 5.1 Key performance indicators for SWE.1 Establishing and monitoring key performance indicators (KPIs) is crucial for assessing the effectiveness of SWE.1 implementation: 5.2 Assessing process maturity Evaluating the maturity of the SWE.1 process helps identify areas for improvement: 5.3 Continuous improvement strategies Adopting a culture of continuous improvement is essential for long-term success in SWE.1: 6. Future Trends in Software Requirements Analysis 6.1 Impact of AI and machine learning on requirements engineering Artificial intelligence and machine learning are poised to revolutionize software requirements analysis: 6.2 Evolving standards and regulations in automotive software The automotive industry is experiencing rapid changes in standards and regulations: 6.3 The role of SWE.1 in emerging automotive technologies SWE.1 will play a crucial role in addressing the challenges posed by emerging automotive technologies: 7. Case Studies: SWE.1 Success Stories 7.1 Overcoming challenges in large-scale automotive projects Case Study: A major European automotive OEM successfully implemented SWE.1 in a complex infotainment system project, resulting in a 30% reduction in requirements-related defects and a 20% improvement in project delivery time. 7.2 Improving efficiency through optimized SWE.1 processes Case Study: A tier-1 supplier streamlined their SWE.1 processes by integrating model-based systems engineering, leading to a 40% reduction in requirements analysis time and improved traceability across the development lifecycle. 7.3 Achieving higher ASPICE maturity levels through SWE.1 excellence Case Study: A mid-sized automotive software company achieved ASPICE Level 3 in SWE.1 through systematic process improvement initiatives, resulting in enhanced customer satisfaction and a 25% increase in new business opportunities. Conclusion: Driving Innovation Through Effective Requirements Analysis The SWE.1 Software Requirements Analysis process is fundamental to developing high-quality automotive software that meets stringent industry standards. By mastering SWE.1, organizations can significantly improve their software development processes, reduce errors, and accelerate time-to-market. As the automotive industry continues to evolve with increasingly complex software systems, the importance of robust requirements analysis cannot be overstated. Effective implementation of SWE.1 enables organizations to: By leveraging best practices, embracing emerging technologies, and maintaining a commitment to continuous improvement, automotive organizations can position themselves at the forefront of software excellence. As the industry moves towards more connected, autonomous, and electrified vehicles, mastering SWE.1 will be crucial for staying competitive and delivering innovative solutions that meet the evolving needs of the automotive market.

Executive Summary The automotive industry is undergoing a rapid digital transformation, with software becoming an increasingly critical component of modern vehicles. As the complexity of automotive systems grows, so does the need for robust verification processes to ensure safety, reliability, and compliance with industry standards. The Automotive SPICE (ASPICE) SYS.5 System Verification process plays a crucial role in this landscape, providing a structured approach to validating that automotive systems meet their specified requirements. This whitepaper delves into the intricacies of the ASPICE SYS.5 System Verification process, offering insights into its implementation, best practices, and the value it brings to automotive software development. By understanding and effectively implementing SYS.5, organizations can significantly enhance their system quality, reduce development costs, and accelerate time-to-market for their automotive software products. 1. Introduction to ASPICE and System Verification 1.1 Overview of Automotive SPICE Automotive SPICE (Software Process Improvement and Capability dEtermination) is a framework specifically designed for assessing and improving software development processes in the automotive industry. It provides a comprehensive set of best practices and guidelines that help organizations develop high-quality software systems for vehicles, ensuring compliance with industry standards and regulatory requirements. 1.2 Importance of System Verification in Automotive Software Development System verification is a critical process in automotive software development, serving as a safeguard against potential defects and ensuring that the final product meets its intended specifications. In the context of increasingly complex automotive systems, which often integrate multiple software and hardware components, thorough verification is essential for: 1.3 SYS.5 Process Purpose and Outcomes The SYS.5 System Verification process, as defined in Automotive SPICE, aims to confirm that the integrated system meets its specified requirements. The primary purposes of this process are: The expected outcomes of the SYS.5 process include: 2. Key Components of SYS.5 System Verification 2.1 Verification Strategy and Planning A well-defined verification strategy is the foundation of an effective SYS.5 process. This strategy should outline: The verification plan should be integrated into the overall project plan and aligned with other development activities. 2.2 Specification of Verification Measures Verification measures are the specific methods and techniques used to verify that the system meets its requirements. These may include: Each verification measure should be clearly defined, including its purpose, scope, and expected results. 2.3 Selection of Verification Measures The selection of appropriate verification measures is crucial for effective system verification. Factors to consider include: A balanced mix of verification measures should be chosen to provide comprehensive coverage of system requirements. 2.4 Verification Execution and Recording The execution of verification measures involves: Detailed records should be maintained for all verification activities, including test cases, test results, and any issues or defects identified. 2.5 Traceability and Consistency Maintaining bidirectional traceability between system requirements and verification measures is a key aspect of the SYS.5 process. This involves: Consistency checks should be performed to ensure that the verification results align with the system requirements and that any changes in requirements are reflected in the verification measures. 3. Best Practices for Implementing SYS.5 3.1 Establishing a Robust Verification Framework To implement SYS.5 effectively, organizations should: 3.2 Integrating Verification into the Development Lifecycle System verification should not be treated as a standalone activity but integrated throughout the development lifecycle. This can be achieved by: 3.3 Leveraging Automation in System Verification Automation can significantly enhance the efficiency and effectiveness of system verification. Key areas for automation include: 3.4 Ensuring Comprehensive Coverage of System Requirements To achieve comprehensive coverage: 4. Challenges and Solutions in System Verification 4.1 Common Pitfalls in Verification Processes Some common challenges in implementing SYS.5 include: 4.2 Strategies for Overcoming Verification Challenges To address these challenges, organizations can: 4.3 Case Studies: Successful SYS.5 Implementations (Note: This section would typically include specific case studies, which are not provided in the search results. Organizations would use their own experiences or industry examples here.) 5. The Future of System Verification in Automotive Software 5.1 Emerging Trends in Verification Techniques The field of system verification is evolving rapidly, with emerging trends including: 5.2 Impact of AI and Machine Learning on Verification Processes AI and machine learning are poised to revolutionize system verification by: 5.3 Preparing for Future ASPICE Updates As ASPICE continues to evolve, organizations should: 6. Measuring Success in SYS.5 Implementation 6.1 Key Performance Indicators for System Verification Effective KPIs for SYS.5 implementation may include: 6.2 Continuous Improvement in Verification Processes Organizations should implement a continuous improvement cycle for their verification processes, including: 6.3 Aligning Verification with Business Objectives To ensure that verification activities contribute to overall business success: 7. Our Approach to ASPICE SYS.5 Consulting 7.1 Tailored Solutions for Different Organization Sizes Our consulting services are designed to meet the needs of organizations of all sizes, from small startups to large enterprises. We offer: 7.2 Integration with Existing Development Processes We work closely with clients to integrate SYS.5 processes into their existing development workflows, ensuring: 7.3 Training and Support for Sustainable Implementation Our comprehensive support includes: Conclusion The ASPICE SYS.5 System Verification process is a critical component in developing high-quality, reliable automotive software systems. By implementing robust verification practices, organizations can significantly reduce defects, improve product quality, and accelerate time-to-market. As the automotive industry continues to evolve, with increasing software complexity and stringent regulatory requirements, effective system verification becomes even more crucial. Organizations that excel in SYS.5 implementation will be better positioned to deliver innovative, safe, and compliant automotive software products. Our expertise in ASPICE consulting, combined with our tailored approach to SYS.5 implementation, enables us to help organizations achieve excellence in system verification. By partnering with us, automotive software developers can enhance their verification processes, improve product quality, and ultimately drive business success in this rapidly changing industry.

Executive Summary In the rapidly evolving automotive industry, where software complexity continues to increase exponentially, the ASPICE (Automotive Software Process Improvement and Capability Determination) model has become a crucial standard for ensuring quality and reliability. Within this framework, the SYS.4 System Integration and Integration Verification process plays a pivotal role in seamlessly combining system elements and validating their interactions. This whitepaper delves deep into the intricacies of ASPICE SYS.4, exploring its key components, implementation strategies, and best practices. By mastering this process, organizations can significantly enhance their system integration outcomes, reduce development cycles, and maintain a competitive edge in the automotive sector. Our analysis draws upon extensive industry experience and cutting-edge methodologies to provide actionable insights for both engineers and executives seeking to optimize their ASPICE compliance and system integration processes. 1. Introduction to ASPICE SYS.4 1.1 Purpose and Scope of SYS.4 The SYS.4 process focuses on the systematic integration of system elements into larger system configurations and the verification of their interactions. Its primary objectives include: 1.2 Key Process Outcomes Successful implementation of SYS.4 results in several critical outcomes: 1.3 Relationship to Other ASPICE Processes SYS.4 is intricately connected with other ASPICE processes, particularly: 2. The System Integration Strategy 2.1 Developing a Robust Integration Plan A well-crafted integration plan is the cornerstone of successful SYS.4 implementation. This plan should: 2.2 Aligning with Project and Release Plans Integration activities must be synchronized with overall project timelines and release schedules. This alignment ensures: 2.3 Identifying System Items and Integration Sequence A systematic approach to identifying system items and determining the integration sequence is crucial. Consider: 3. Verification Measures and Selection 3.1 Specifying Verification Measures Effective verification measures are essential for validating the integrated system. Key aspects include: 3.2 Criteria for Selecting Verification Measures Selection of appropriate verification measures should be based on: 3.3 Regression Testing Strategy A robust regression testing strategy is vital for managing system changes and ensuring continued functionality. Consider: 4. Integration and Verification Execution 4.1 Step-by-Step Integration Process A structured integration process typically involves: 4.2 Performing Integration Verification Verification activities should be systematic and thorough: 4.3 Recording and Analyzing Results Meticulous recording and analysis of integration results are crucial: 5. Traceability and Consistency 5.1 Establishing Bidirectional Traceability Bidirectional traceability between system requirements and integrated items is a key ASPICE requirement. This involves: 5.2 Ensuring Consistency with System Architecture The integrated system must align with the defined system architecture: 5.3 Tools and Techniques for Maintaining Traceability Effective traceability management often requires specialized tools: 6. Communication and Reporting 6.1 Summarizing Integration and Verification Results Clear and concise reporting of integration outcomes is essential: 6.2 Effective Communication with Stakeholders Regular and transparent communication ensures alignment across the organization: 6.3 Addressing Non-Conformances A structured approach to handling non-conformances is crucial: 7. Challenges and Best Practices 7.1 Common Implementation Challenges Organizations often face several challenges in implementing SYS.4: 7.2 Industry Best Practices Leading organizations employ several best practices to overcome these challenges: 7.3 Continuous Improvement Strategies Continuous improvement is key to long-term success in SYS.4 implementation: Conclusion Mastering the ASPICE SYS.4 System Integration and Integration Verification process is crucial for delivering high-quality, integrated automotive systems. By implementing robust integration strategies, leveraging advanced verification techniques, and maintaining rigorous traceability, organizations can significantly enhance their development processes, reduce errors, and ultimately deliver more reliable products to market faster. The automotive industry continues to evolve rapidly, with increasing software complexity and stringent quality requirements. In this challenging environment, excellence in system integration and verification becomes a key differentiator. Organizations that invest in optimizing their SYS.4 processes not only ensure ASPICE compliance but also position themselves as leaders in automotive software development. Our company’s expertise in ASPICE consulting can provide invaluable support in navigating these complexities. By partnering with us, you gain access to industry-leading methodologies, tools, and best practices that can transform your system integration processes. Together, we can help you achieve and maintain excellence in ASPICE compliance, driving innovation and quality in your automotive software development initiatives.

Executive Summary The ASPICE SYS.3 System Architectural Design process is a critical component of automotive software development, playing a pivotal role in ensuring the quality, reliability, and efficiency of complex vehicle systems. This whitepaper provides a comprehensive exploration of SYS.3, offering insights into its implementation, best practices, and future trends. By mastering this process, organizations can significantly enhance their product development lifecycle, reduce costs, and improve time-to-market. Our company’s expertise in ASPICE consulting positions us uniquely to guide automotive manufacturers and suppliers through the intricacies of SYS.3, ultimately leading to superior system architectures and more competitive products in the global automotive market. 1. Introduction to ASPICE SYS.3 System Architectural Design 1.1 Definition and Purpose The SYS.3 System Architectural Design process is a fundamental component of the Automotive Software Process Improvement and Capability Determination (ASPICE) framework. Its primary purpose is to establish a cohesive system architectural design that effectively realizes the specified system requirements. This process involves creating a comprehensive structure for the system, defining system elements, and specifying their interfaces to ensure seamless integration and functionality. 1.2 Role in the ASPICE Framework Within the ASPICE framework, SYS.3 serves as a crucial bridge between system requirements and detailed design. It translates high-level system requirements into a structured architectural blueprint, providing a foundation for subsequent development stages. The process ensures that all system components are well-defined, properly integrated, and aligned with the overall system objectives. 1.3 Key Outcomes and Objectives The SYS.3 process aims to achieve several key outcomes: 2. The SYS.3 Process in Detail 2.1 Developing System Architectural Design The development of a system architectural design begins with analyzing the system requirements to identify key structural elements and their relationships. This involves: 2.2 Allocating System Requirements Once the architectural structure is established, system requirements are allocated to specific system elements. This process ensures that: 2.3 Defining Interfaces of System Elements Interface definition is crucial for ensuring seamless integration of system elements. This involves: 2.4 Describing Dynamic Behavior The dynamic behavior of the system is described to capture its operational characteristics: 2.5 Evaluating Alternative System Architectures To ensure the optimal architectural solution, alternative designs are evaluated based on: 3. Best Practices for Implementing SYS.3 3.1 Establishing Bidirectional Traceability Maintaining bidirectional traceability between system requirements and architectural elements is essential for: 3.2 Ensuring Consistency Consistency across the architectural design is crucial for system integrity: 3.3 Communicating Agreed System Architectural Design Effective communication of the architectural design is vital for successful implementation: 4. Challenges and Solutions in SYS.3 Implementation 4.1 Common Pitfalls Organizations often encounter challenges when implementing SYS.3: 4.2 Strategies for Overcoming Obstacles To address these challenges, organizations can: 4.3 Case Studies of Successful Implementations (Note: Specific case studies would be included here, showcasing successful SYS.3 implementations and their outcomes.) 5. Tools and Techniques for Effective System Architectural Design 5.1 Modeling and Simulation Tools Advanced modeling and simulation tools play a crucial role in SYS.3 implementation: 5.2 Documentation and Traceability Tools Efficient documentation and traceability are supported by: 5.3 Collaboration and Communication Platforms Effective collaboration is facilitated by: 6. Measuring Success: KPIs for SYS.3 6.1 Quality Metrics Key quality metrics for SYS.3 include: 6.2 Efficiency Metrics Efficiency can be measured through: 6.3 Compliance Metrics Compliance with ASPICE standards is assessed by: 7. Future Trends in System Architectural Design 7.1 Emerging Technologies The future of system architectural design is being shaped by: 7.2 Evolving Industry Standards Industry standards continue to evolve, influencing SYS.3 practices: 7.3 Predictions for the Next Decade Looking ahead, we anticipate: Conclusion The ASPICE SYS.3 System Architectural Design process is a cornerstone of successful automotive software development. By mastering this process, organizations can significantly enhance their ability to create robust, efficient, and innovative vehicle systems. The challenges in implementing SYS.3 are outweighed by the substantial benefits it brings in terms of product quality, development efficiency, and market competitiveness. As the automotive industry continues to evolve, with increasing complexity in vehicle systems and growing emphasis on electric and autonomous technologies, the importance of effective system architectural design will only grow. Organizations that invest in developing their SYS.3 capabilities now will be well-positioned to lead in this dynamic landscape. Our company’s deep expertise in ASPICE consulting, combined with our comprehensive understanding of the SYS.3 process, positions us as an ideal partner for automotive manufacturers and suppliers seeking to excel in system architectural design. By leveraging our knowledge, tools, and best practices, organizations can not only achieve compliance with ASPICE standards but also drive innovation and efficiency in their product development processes. In an industry where quality, safety, and time-to-market are paramount, mastering the SYS.3 process is not just a compliance requirement—it’s a competitive advantage. Let us help you transform your system architectural design process and pave the way for the next generation of automotive excellence.

Executive Summary The Automotive SPICE (ASPICE) System Requirements Analysis process is a critical component in the development of high-quality, reliable automotive software systems. This whitepaper provides a comprehensive overview of the SYS.2 process, offering insights into best practices, challenges, and strategies for effective implementation. By mastering this process, automotive companies can significantly improve product quality, reduce development costs, and accelerate time-to-market. This document serves as a guide for engineers and executives seeking to enhance their organization’s capabilities in system requirements analysis and achieve higher ASPICE maturity levels. 1. Introduction to ASPICE and System Requirements Analysis Automotive SPICE (ASPICE) is a framework for assessing and improving software development processes in the automotive industry. It is based on the ISO/IEC 15504 standard and has been tailored to address the specific needs and challenges of automotive software development. The System Requirements Analysis process, designated as SYS.2 in ASPICE, plays a pivotal role in translating stakeholder requirements into a set of system requirements that guide the entire development process. This process is crucial for several reasons: Key challenges faced by automotive companies in requirements management include: 2. Overview of the SYS.2 System Requirements Analysis Process Purpose and Objectives The primary purpose of the SYS.2 process is to transform the stakeholder requirements into a set of system requirements that will guide the technical implementation of the system. The main objectives include: Process Outcomes and Base Practices ASPICE defines several key outcomes for the SYS.2 process: To achieve these outcomes, ASPICE prescribes several base practices: Relationship to Other ASPICE Processes The SYS.2 process is closely related to several other ASPICE processes: 3. Best Practices for Specifying and Structuring System Requirements Characteristics of Well-Defined System Requirements Well-defined system requirements should be: Techniques for Requirement Elicitation and Documentation Effective requirement elicitation techniques include: For documentation, consider using: Strategies for Prioritizing and Categorizing Requirements Prioritization methods: Categorization approaches: 4. Analyzing System Requirements for Correctness and Feasibility Methods for Validating Requirement Quality Assessing Technical Feasibility and Impact on Project Estimates Analyzing Interdependencies Between Requirements 5. Ensuring Traceability and Consistency Establishing Bidirectional Traceability with Stakeholder Requirements Tools and Techniques for Maintaining Requirement Consistency The Importance of Impact Analysis on the Operating Environment 6. Verification and Communication of System Requirements Developing Effective Verification Criteria Strategies for Communicating Requirements to All Affected Parties Managing Requirement Changes and Updates 7. Overcoming Common Challenges in System Requirements Analysis Dealing with Ambiguous or Conflicting Requirements Balancing Detail and Flexibility in Requirements Specification Integrating Requirements Analysis into Agile Development Processes Conclusion: Maximizing the Value of System Requirements Analysis Effective system requirements analysis is crucial for the success of automotive software development projects. By implementing the best practices and strategies outlined in this whitepaper, organizations can: By investing in robust system requirements analysis processes, automotive companies can drive innovation, improve customer satisfaction, and maintain a competitive edge in an increasingly complex and demanding market.

Executive Summary The Automotive SPICE (ASPICE) SYS.1 Requirements Elicitation process is a cornerstone of successful automotive software development. This whitepaper provides an in-depth exploration of SYS.1, offering valuable insights into best practices, challenges, and innovative approaches to requirements elicitation. By mastering this process, organizations can significantly enhance their software development lifecycle, minimize errors, and improve overall product quality. In the rapidly evolving automotive industry, where software complexity continues to increase, the ability to accurately capture and translate stakeholder needs into system requirements is more critical than ever. This whitepaper aims to position our company as a thought leader in ASPICE consulting by providing a comprehensive guide to the SYS.1 process, its implementation, and its impact on automotive software development. 1. Introduction to ASPICE SYS.1 Requirements Elicitation 1.1 Definition and Purpose The ASPICE SYS.1 Requirements Elicitation process is a systematic approach to identifying, documenting, and managing stakeholder requirements for automotive software systems. Its primary purpose is to ensure that all relevant stakeholder needs and expectations are captured, understood, and translated into a set of system requirements that will guide the development process. 1.2 The Role of SYS.1 in the ASPICE Framework SYS.1 is a fundamental process within the ASPICE framework, serving as the foundation for subsequent system development activities. It is part of the System Engineering process group and directly influences other processes such as SYS.2 (System Requirements Analysis) and SYS.3 (System Architectural Design). The success of these downstream processes heavily depends on the quality and completeness of the requirements elicited during SYS.1. 1.3 Key Outcomes and Base Practices The SYS.1 process aims to achieve several key outcomes: To achieve these outcomes, ASPICE defines several base practices for SYS.1: 2. The Requirements Elicitation Process 2.1 Stakeholder Identification and Engagement The first step in effective requirements elicitation is identifying and engaging with all relevant stakeholders. This includes not only end-users but also regulatory bodies, suppliers, internal teams, and other parties affected by or influencing the system. Stakeholder mapping techniques can be employed to visualize relationships and prioritize engagement efforts. 2.2 Techniques for Gathering Requirements Several techniques can be used to gather requirements effectively: 2.3 Documenting and Structuring Requirements Proper documentation of requirements is crucial for their effective management and implementation. Requirements should be: Structured formats such as user stories, use cases, or formal requirement specifications can be used to document requirements systematically. 2.4 Analyzing and Prioritizing Requirements Once requirements are gathered, they must be analyzed for completeness, consistency, and feasibility. Prioritization techniques such as MoSCoW (Must have, Should have, Could have, Won’t have) or the Kano model can be employed to ensure that the most critical requirements are addressed first. 3. Challenges in Requirements Elicitation 3.1 Communication Barriers Effective communication between technical teams and non-technical stakeholders can be challenging. Misunderstandings due to jargon, cultural differences, or varying levels of technical expertise can lead to incorrect or incomplete requirements. 3.2 Evolving Stakeholder Needs Stakeholder needs may change over time due to market shifts, technological advancements, or regulatory changes. Managing these evolving requirements while maintaining project scope and timeline can be difficult. 3.3 Ambiguity and Inconsistency in Requirements Stakeholders may express requirements in vague or conflicting terms. Resolving these ambiguities and inconsistencies is crucial for developing a clear, actionable set of requirements. 3.4 Balancing Conflicting Stakeholder Interests Different stakeholders may have conflicting requirements or priorities. Balancing these competing interests while ensuring the overall system meets its objectives is a significant challenge in the elicitation process. 4. Best Practices for Effective Requirements Elicitation 4.1 Establishing Clear Communication Channels Implementing structured communication protocols and using collaborative platforms can facilitate clear, ongoing dialogue between stakeholders and development teams. 4.2 Utilizing Visualization Techniques Visual models such as prototypes, wireframes, and process flow diagrams can help stakeholders better understand and articulate their requirements. 4.3 Implementing Traceability Measures Establishing a robust traceability matrix ensures that each requirement can be traced back to its source and forward to its implementation, facilitating impact analysis and change management. 4.4 Continuous Stakeholder Engagement Regular check-ins and iterative reviews with stakeholders throughout the development process help ensure that requirements remain aligned with stakeholder needs and expectations. 4.5 Leveraging Prototyping and Simulation Rapid prototyping and simulation techniques allow stakeholders to interact with early versions of the system, providing valuable feedback and uncovering hidden requirements. 5. Innovative Approaches to Requirements Elicitation 5.1 AI-Assisted Requirements Analysis Artificial Intelligence and Natural Language Processing techniques can be employed to analyze large volumes of stakeholder input, identify patterns, and suggest potential requirements. 5.2 Virtual Reality for Requirements Visualization Virtual Reality (VR) technologies can create immersive environments for stakeholders to experience and interact with proposed systems, leading to more accurate and comprehensive requirements. 5.3 Crowdsourcing Requirements Leveraging crowdsourcing platforms can provide diverse perspectives and innovative ideas for system requirements, especially for consumer-facing automotive software. 5.4 Data-Driven Requirements Elicitation Analyzing user behavior data, market trends, and operational metrics can inform the requirements elicitation process, leading to more data-driven decision-making. 6. Measuring Success in Requirements Elicitation 6.1 Key Performance Indicators (KPIs) for SYS.1 Establishing and monitoring KPIs such as requirement clarity, completeness, and stakeholder satisfaction can help gauge the effectiveness of the elicitation process. 6.2 Tools for Requirements Quality Assessment Automated tools can be used to assess the quality of requirements, checking for attributes such as clarity, testability, and consistency. 6.3 Continuous Improvement Strategies Implementing feedback loops and lessons learned sessions can drive continuous improvement in the requirements elicitation process. 7. Future Trends in Requirements Elicitation 7.1 Integration with Agile Methodologies As the automotive industry increasingly adopts agile methodologies, requirements elicitation processes will need to adapt to more iterative and flexible approaches. 7.2 Machine Learning in Requirements Analysis Advanced machine learning algorithms are expected to play a larger role in analyzing and predicting stakeholder needs based on historical data and market trends. 7.3 Blockchain for Requirements Traceability Blockchain technology could revolutionize requirements traceability, providing an immutable and transparent record of requirement changes and approvals. Conclusion: Elevating Your Requirements Elicitation Process Mastering the ASPICE SYS.1 Requirements Elicitation process is crucial for automotive software development

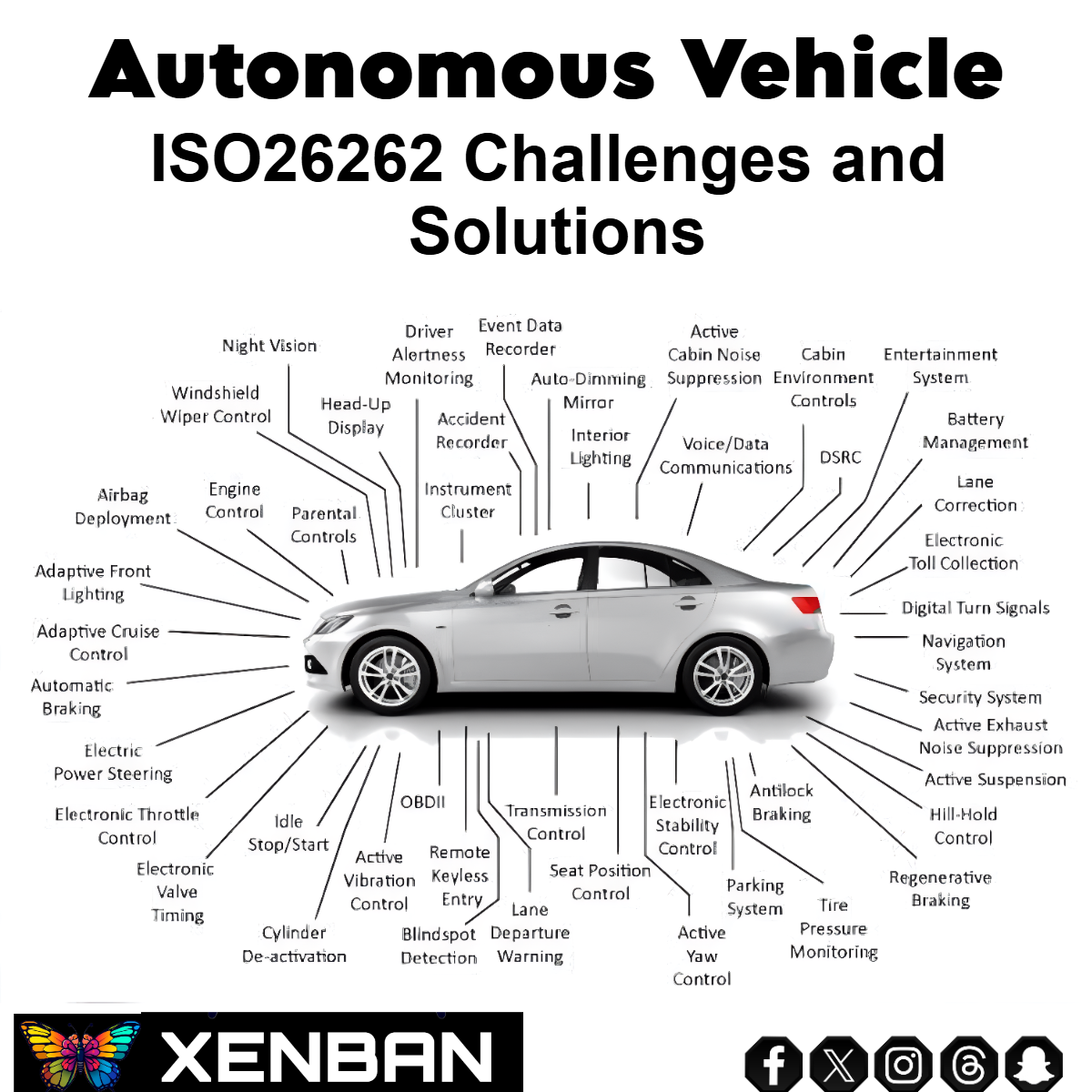

In the rapidly evolving landscape of automotive technology, electric and autonomous vehicles are at the forefront of innovation. As these cutting-edge technologies continue to advance, ensuring functional safety becomes increasingly critical. ISO 26262, the international standard for functional safety in road vehicles, plays a pivotal role in this landscape. However, applying this standard to electric and autonomous vehicles presents unique challenges that require innovative solutions. This article explores these challenges in depth and offers potential solutions for manufacturers and developers, including how Xenban’s expertise can support this crucial process. Understanding ISO 26262 in the Context of Modern Vehicles ISO 26262 is an adaptation of the IEC 61508 functional safety standard specifically tailored for automotive electric/electronic (E/E) systems. It provides a comprehensive framework for managing functional safety throughout a vehicle’s lifecycle, from concept to decommissioning. The standard aims to ensure that safety-critical systems in vehicles operate correctly or fail in a predictable manner to minimize risks. Key Aspects of ISO 26262: Challenges in Applying ISO 26262 to Electric and Autonomous Vehicles 1. System Complexity Electric and autonomous vehicles incorporate numerous sensors, cameras, LiDAR systems, and other components, each with its own set of safety requirements. This complexity makes it challenging to ensure all safety requirements are met and potential hazards are identified and mitigated. Xenban Solution: Xenban’s advanced system modeling tools can help manage this complexity by providing a comprehensive view of all system components and their interactions. This holistic approach enables more effective hazard identification and risk assessment. 2. Software Reliability and Security The algorithms and software used in autonomous vehicles must be exceptionally reliable and secure. Rigorous development processes, including thorough testing, verification, and validation, are necessary. Additionally, ensuring the software is protected against cyber attacks is crucial. Xenban Approach: Xenban’s software development lifecycle management tools incorporate advanced security measures and rigorous testing protocols, helping ensure both reliability and security in autonomous vehicle software. 3. Environmental Adaptability Autonomous vehicles must operate safely in a wide range of conditions and environments. They need to react to various potential hazards, including other vehicles, pedestrians, adverse weather, and road construction. Xenban Solution: Xenban’s simulation tools offer advanced environmental modeling capabilities, allowing developers to test autonomous systems in a wide range of virtual scenarios, ensuring adaptability and safety across diverse conditions. 4. Machine Learning and AI Integration The use of artificial intelligence (AI) and machine learning (ML) in autonomous driving systems introduces new challenges. Traditional safety paradigms may not adequately address the statistical nature of ML algorithms’ performance. Xenban Approach: Xenban’s AI safety assessment tools are specifically designed to evaluate and validate AI/ML systems in the context of ISO 26262, helping bridge the gap between traditional safety standards and cutting-edge AI technologies. 5. Expanding Scope Beyond E/E Systems While ISO 26262 primarily focuses on E/E systems, autonomous vehicles also rely heavily on mechanical and electromechanical systems that are susceptible to safety-related degradation and failure. Xenban Solution: Xenban offers integrated safety assessment tools that consider both E/E and mechanical systems, providing a more comprehensive safety evaluation for autonomous vehicles. Solutions and Strategies 1. Comprehensive Safety Case Development Create a thorough safety case for autonomous vehicles that demonstrates all safety requirements have been met and potential hazards have been identified and mitigated. This requires a detailed understanding of the systems involved and a rigorous methodology for risk analysis and hazard assessment. Xenban’s Role: Xenban’s safety case management platform provides a structured environment for developing, documenting, and maintaining comprehensive safety cases, ensuring all aspects of ISO 26262 are addressed. 2. Modular Software Design Implement a modular approach to software design, where each system component is developed and tested separately before integration. This method helps ensure all safety requirements are met and gives developers more control over the development process. Xenban’s Contribution: Xenban’s software development tools support modular design practices, enabling efficient development, testing, and integration of autonomous vehicle software components. 3. Advanced Simulation and Testing Utilize sophisticated simulation and testing methods, such as hardware-in-the-loop testing and virtual testing, to verify the safety of autonomous vehicles in various environments. These techniques can help address the challenges of testing in real-world scenarios. Xenban’s Expertise: Xenban offers state-of-the-art simulation and testing platforms that enable comprehensive virtual testing of autonomous systems, reducing the need for extensive real-world testing and accelerating development cycles. 4. Adaptive Safety Concepts Develop adaptive safety concepts that can handle the dynamic nature of AI and ML systems. This may involve real-time monitoring of system performance and the ability to switch to fail-safe modes when necessary. Xenban’s Innovation: Xenban’s adaptive safety monitoring tools provide real-time analysis of AI/ML system performance, enabling rapid detection of anomalies and activation of fail-safe mechanisms when required. 5. Extending ISO 26262 Scope Consider extending the scope of ISO 26262 to address mechanical and electromechanical systems in autonomous vehicles. This holistic approach can help ensure comprehensive safety coverage. Xenban’s Approach: Xenban’s integrated safety assessment platform considers both E/E and mechanical systems, providing a more comprehensive safety evaluation that aligns with the extended scope of ISO 26262. 6. Enhanced Hazard Analysis and Risk Assessment (HARA) Implement a more robust HARA process that accounts for the unique challenges of electric and autonomous vehicles. This should include consideration of AI/ML limitations, environmental factors, and potential cyber security threats. Xenban’s Solution: Xenban’s advanced HARA tools incorporate AI/ML considerations, environmental factors, and cybersecurity assessments, providing a more comprehensive hazard analysis for autonomous vehicles. Conclusion Applying ISO 26262 to electric and autonomous vehicles is a complex but necessary endeavor. While challenges exist in areas such as system complexity, software reliability, and the integration of AI/ML technologies, solutions are emerging. By adopting comprehensive safety strategies, leveraging advanced testing methods, and potentially expanding the scope of the standard, the automotive industry can work towards ensuring the safety of these revolutionary vehicles. As the technology continues to evolve, so too must our approaches to functional safety. Collaboration between automakers, technology providers, and regulatory bodies will be crucial in refining and adapting safety standards to meet the unique demands of electric and

In the rapidly evolving landscape of automotive technology, functional safety has become a cornerstone of development and innovation. As vehicles become increasingly complex and reliant on sophisticated electronic systems, ensuring their safety is more critical than ever. This is where ISO 26262, the international standard for functional safety in road vehicles, comes into play. In this comprehensive article, we’ll explore how ISO 26262 is shaping the automotive industry through real-world case studies, and how innovative solutions like Xenban are revolutionizing the implementation of this crucial standard. Understanding ISO 26262: The Foundation of Automotive Functional Safety ISO 26262 is a comprehensive international standard that provides a framework for developing, testing, and validating the safety of electrical and electronic (E/E) systems in automobiles. It aims to ensure that these systems operate safely, even in the event of hardware or software failures. Key Aspects of ISO 26262: The Impact of ISO 26262 on Automotive Development The introduction of ISO 26262 has significantly influenced how automotive companies approach system development. It has led to: Real-World Case Studies Let’s delve into some real-world case studies that demonstrate the practical application of ISO 26262 in the automotive industry. Case Study 1: Steering Column Lock Controller A high-volume passenger car manufacturer needed to develop a Steering Column Lock Controller (SCLC) in compliance with ISO 26262. The development team faced the challenge of meeting ASIL D requirements, the highest safety integrity level. Approach: Outcome:The SCLC successfully met ASIL D requirements, ensuring the highest level of safety for this critical component. This case study demonstrates the importance of rigorous design and testing processes in achieving ISO 26262 compliance for high-integrity systems. Case Study 2: Fuel Level Estimation and Display System A truck manufacturer aimed to develop a Fuel Level Estimation and Display System (FLEDS) compliant with ISO 26262. Challenges: Solution: Result:The FLEDS achieved ISO 26262 compliance, significantly reducing the risk of fuel-related hazards. This case study highlights the importance of comprehensive risk assessment and robust system design in meeting safety standards. Case Study 3: Autonomous Shuttle Program A real-world implementation of an unmanned shuttle program in the Netherlands and Germany showcased the application of ISO 26262 in autonomous vehicles. Key Aspects: Implementation: Outcome:The program successfully demonstrated the safe operation of autonomous shuttles in urban environments, paving the way for future deployments. This case study illustrates the application of ISO 26262 principles to emerging technologies and the importance of considering the broader ecosystem in safety design. Lessons Learned and Best Practices Through these case studies, several key lessons emerge: The Role of Xenban in Streamlining ISO 26262 Compliance As the complexity of automotive systems increases, managing the ISO 26262 compliance process becomes increasingly challenging. This is where innovative solutions like Xenban come into play. Xenban offers a comprehensive platform designed specifically for automotive engineers and executives to streamline the implementation of ISO 26262. Key Features of Xenban: By leveraging Xenban, automotive companies can significantly reduce the time and effort required to achieve ISO 26262 compliance, allowing them to focus on innovation and product development. The Future of Automotive Safety As the automotive industry moves towards higher levels of automation and electrification, the role of ISO 26262 will only grow in importance. Future developments may include: Conclusion ISO 26262 has proven to be a cornerstone in ensuring the functional safety of modern vehicles. Through real-world case studies, we can see its practical application and the tangible benefits it brings to automotive safety. As the industry continues to evolve, this standard will undoubtedly play a crucial role in shaping the future of safe and reliable transportation. By embracing ISO 26262 and learning from these case studies, automotive companies can not only meet regulatory requirements but also build safer, more reliable vehicles that inspire consumer confidence and drive innovation in the industry. Tools like Xenban are instrumental in this process, offering a streamlined approach to ISO 26262 compliance that aligns with the fast-paced nature of modern automotive development. As we look to the future, the principles embodied in ISO 26262 will continue to guide the development of increasingly complex and autonomous vehicles, ensuring that safety remains at the forefront of automotive innovation. Notice: JavaScript is required for this content.

In the rapidly evolving landscape of autonomous vehicles (AVs), ensuring safety has become a paramount challenge for the automotive industry. Two key standards have emerged as the pillars of AV safety: ISO 26262 for functional safety and ISO 21448 for Safety of the Intended Functionality (SOTIF). This comprehensive article delves into how these standards work in tandem to create a robust safety framework for autonomous vehicles, explores the challenges they face, and presents innovative solutions, including how Xenban’s cutting-edge tools are revolutionizing this space. Understanding ISO 26262 and SOTIF ISO 26262: The Cornerstone of Functional Safety ISO 26262, titled “Road vehicles – Functional safety,” is the automotive industry’s standard for ensuring the safety of electrical and electronic (E/E) systems in vehicles. This standard is crucial because it: Key Aspects of ISO 26262: Xenban’s ISO 26262 Solution: Xenban’s ISO 26262 compliance tool streamlines the implementation of this standard by providing: SOTIF (ISO 21448): Addressing the Gaps While ISO 26262 focuses on system malfunctions, SOTIF extends the safety net to address potential hazards arising from the intended functionality of autonomous systems, even when all components are working correctly. SOTIF concentrates on: Key Aspects of SOTIF: Xenban’s SOTIF Integration: Xenban’s platform seamlessly integrates SOTIF considerations into the development process by: Challenges in Implementing ISO 26262 and SOTIF for AVs Complexity of Autonomous Systems The intricate nature of AV systems, with their myriad sensors, cameras, and AI components, presents a significant challenge in ensuring all safety requirements are met. This complexity makes it difficult to: Xenban’s Complexity Management: Our advanced system modeling tools help visualize and manage complex AV architectures, enabling: Machine Learning and AI Algorithms Traditional safety paradigms struggle with the statistical nature of machine learning algorithms used in AVs. This presents unique challenges: Xenban’s AI Safety Suite: Our cutting-edge AI safety tools address these challenges by: Environmental Variability AVs must operate safely in a wide range of conditions, from adverse weather to unexpected road scenarios. This variability poses significant challenges for safety assurance: Xenban’s Environmental Simulation: Our advanced simulation platform allows for: Human-Machine Interaction As automation increases, new risks emerge from changes in driver behavior and potential overreliance on autonomous systems: Xenban’s HMI Analysis Tools: Our specialized human-machine interaction analysis suite enables: Solutions and Strategies Integrated Safety Approach Combining ISO 26262 and SOTIF creates a more comprehensive safety framework. This integration allows for addressing both system malfunctions and performance limitations. Xenban’s Integrated Platform: Our unified safety platform seamlessly combines ISO 26262 and SOTIF methodologies, providing: Advanced Simulation and Testing Utilizing sophisticated simulation techniques, including hardware-in-the-loop testing and virtual environments, can help validate AV safety in various scenarios. Xenban’s Simulation Environment: Our state-of-the-art simulation tools offer: Scenario-Based Testing Developing a comprehensive database of edge cases and rare scenarios is crucial for SOTIF compliance. This approach helps in identifying and mitigating potential hazards. Xenban’s Scenario Database: Our extensive scenario library includes: AI and Machine Learning for Safety Leveraging AI and ML can aid in building a robust database of scenarios, improving the training and testing of AV neural networks. Xenban’s AI-Driven Safety: Our AI-powered safety assessment tools provide: Modular Software Design Implementing a modular approach to software development allows for better control and testing of individual components before integration into the complete system. Xenban’s Software Architecture Platform: Our development environment supports: The Road Ahead As the automotive industry continues to push the boundaries of autonomous technology, the evolution of safety standards must keep pace. The collaboration between ISO 26262 and SOTIF provides a solid foundation, but ongoing research and development are necessary to address emerging challenges. Future Directions Xenban’s Vision: At Xenban, we’re committed to staying at the forefront of these developments. Our research team is actively working on: Conclusion Bridging the gap between ISO 26262 and SOTIF is crucial for ensuring the safety of autonomous vehicles. By addressing both functional safety and the safety of intended functionality, the automotive industry can build trust in AV technology and pave the way for safer, more reliable autonomous transportation. As we move forward, continuous improvement of these standards and their implementation will be key to overcoming the unique challenges posed by autonomous vehicles. With Xenban’s cutting-edge tools and a commitment to rigorous safety practices, the vision of safe, fully autonomous vehicles on our roads is becoming a tangible reality. Xenban stands ready to partner with automotive manufacturers and suppliers in this exciting journey, providing the expertise and tools needed to navigate the complex landscape of AV safety. Our comprehensive suite of solutions, from ISO 26262 and SOTIF compliance tools to advanced AI-driven safety assessment platforms, empowers organizations to: By choosing Xenban, you’re not just adopting a set of tools – you’re embracing a holistic approach to AV safety that will drive innovation and excellence in your autonomous vehicle programs. Together, we can create a future where autonomous vehicles not only meet but exceed the highest safety standards, revolutionizing transportation and enhancing lives around the globe. Notice: JavaScript is required for this content.

In the rapidly evolving automotive industry, two seemingly conflicting methodologies have emerged as critical components of software development: ISO 26262 functional safety standards and Agile development practices. While ISO 26262 emphasizes rigorous documentation and systematic processes, Agile promotes flexibility and iterative development. This article explores how these two approaches can be harmoniously integrated to create safer, more efficient automotive software development processes, with insights from industry leaders like Xenban. Understanding ISO 26262 ISO 26262 is an international standard for functional safety in automotive electrical and electronic systems. It provides a comprehensive framework for managing safety-related aspects throughout the entire product lifecycle, from concept to decommissioning. The standard introduces Automotive Safety Integrity Levels (ASILs) to classify risk and determine the necessary safety measures. Key components of ISO 26262 include: The Agile Approach Agile methodologies focus on iterative development, continuous feedback, and adaptability to change. Core principles of Agile include: Challenges in Combining ISO 26262 and Agile The integration of ISO 26262 and Agile practices presents several challenges: Bridging the Gap: Strategies for Integration Despite these challenges, several strategies can help bridge the gap between ISO 26262 and Agile development: 1. Tailored Agile Practices Adapt Agile methodologies to incorporate safety-critical requirements. For example, companies like Xenban offer expertise in functional safety management, helping organizations tailor their Agile practices to meet ISO 26262 standards. 2. Incremental Safety Analysis Integrate safety analysis into each sprint, ensuring that safety requirements are considered throughout the development process. This approach allows for continuous assessment and mitigation of potential hazards. 3. Automated Documentation Leverage tools and automation to generate necessary documentation from code and development artifacts. This reduces the manual documentation burden while maintaining compliance with ISO 26262 requirements. 4. Cross-functional Teams Form teams that include both development and safety experts. Xenban’s functional safety engineers, for instance, collaborate with cross-functional teams to define safety requirements, conduct safety analyses, and develop comprehensive safety documentation. 5. Continuous Integration and Testing Implement robust continuous integration and testing practices that incorporate safety-related tests. This helps identify and address safety issues early in the development cycle. 6. Agile Safety Case Development Develop safety cases incrementally, aligning with the Agile development process. This allows for continuous refinement and validation of safety arguments. Best Practices for Implementation To successfully integrate ISO 26262 and Agile development, consider the following best practices: The Role of Specialized Expertise Companies like Xenban play a crucial role in bridging the gap between ISO 26262 and Agile development. Their functional safety engineers are skilled in ensuring compliance with industry standards such as ISO 26262 and ASPICE while working within Agile frameworks. These experts can: By leveraging such expertise, automotive companies can ensure that their Agile development practices align with the rigorous safety requirements of ISO 26262. Conclusion While integrating ISO 26262 and Agile development presents challenges, it also offers significant opportunities for improving the safety and efficiency of automotive software development. By adopting tailored approaches, leveraging automation, and fostering a culture of safety-conscious agility, organizations can create a development environment that is both compliant with functional safety standards and responsive to change. As the automotive industry continues to evolve, the successful integration of ISO 26262 and Agile methodologies will be crucial in delivering safe, innovative software solutions that meet the demands of modern vehicles. Companies like Xenban are at the forefront of this integration, offering specialized services that help automotive businesses navigate the complexities of functional safety in an Agile world. By bridging the gap between these two approaches, automotive companies can ensure they remain at the forefront of both safety and innovation, delivering high-quality, safe software solutions efficiently and effectively. Notice: JavaScript is required for this content.