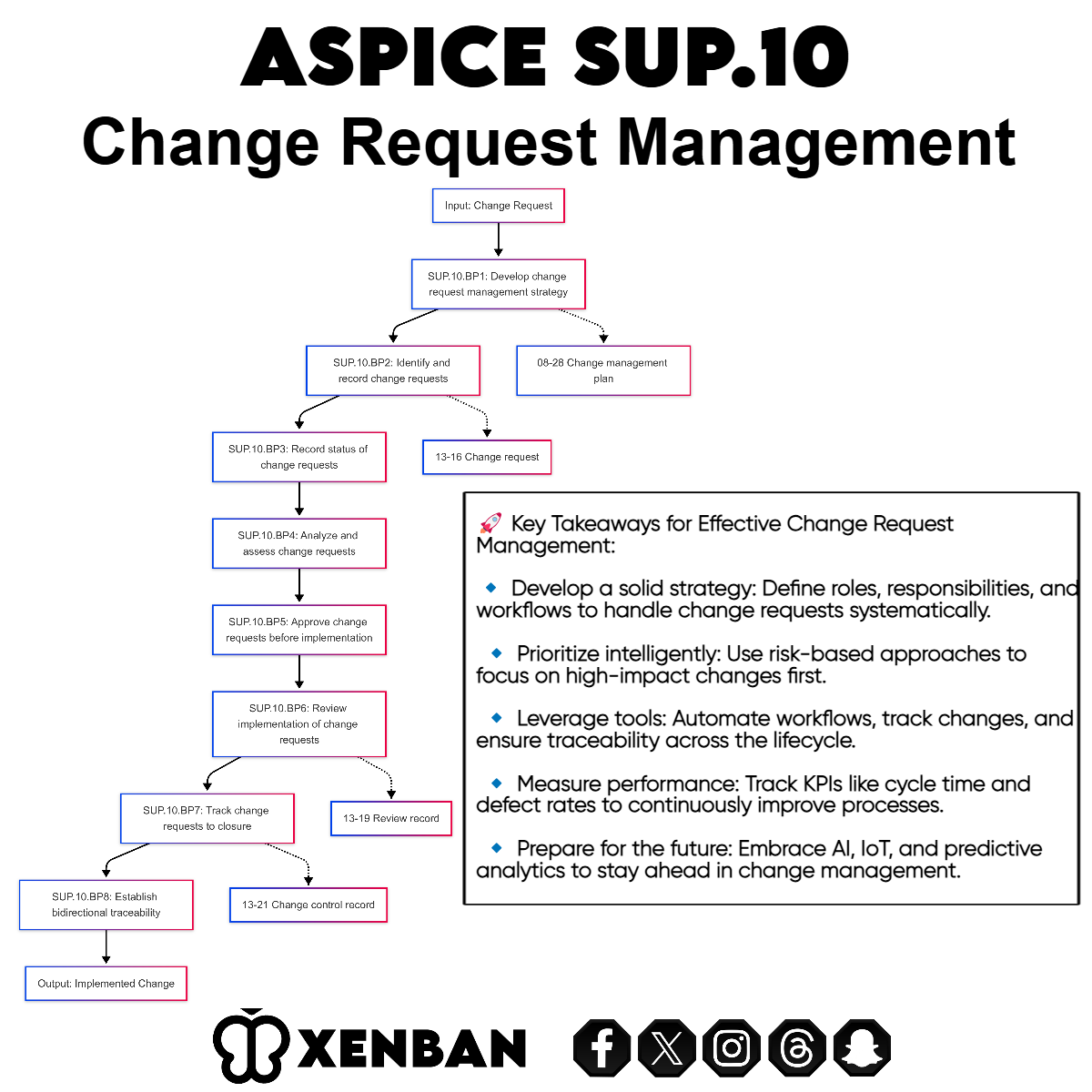

Executive Summary In the rapidly evolving automotive industry, effective change request management has become a critical factor in ensuring the quality, reliability, and safety of software systems. Automotive SPICE (ASPICE) SUP.10 Change Request Management plays a pivotal role in managing the complexity of automotive software development and maintaining compliance with industry standards. This whitepaper delves into the intricacies of ASPICE SUP.10, exploring its significance, implementation strategies, and best practices. We examine the challenges faced by automotive software developers in managing change requests and provide insights into overcoming these obstacles. By leveraging data-driven approaches and embracing emerging technologies, organizations can not only achieve ASPICE compliance but also elevate their change request management processes to new heights. Our company’s unique approach combines deep industry expertise with cutting-edge tools and methodologies, enabling automotive manufacturers and suppliers to navigate the complexities of ASPICE SUP.10 with confidence. Through this whitepaper, we aim to demonstrate our thought leadership in ASPICE consulting and showcase how our solutions address the critical challenges in change request management. I. Introduction to ASPICE and SUP.10 A. Overview of Automotive SPICE Automotive SPICE (Software Process Improvement and Capability dEtermination) is a framework specifically designed for assessing and improving software development processes in the automotive industry. Based on the ISO/IEC 15504 standard, ASPICE has been tailored to meet the unique challenges and requirements of automotive software development. ASPICE provides a structured approach to process assessment and improvement, enabling organizations to: B. Importance of Change Request Management in Automotive Software Development As vehicles become increasingly software-dependent, the management of change requests has become crucial. Effective change request management: C. Brief Introduction to SUP.10 Process SUP.10 Change Request Management is a supporting process within the ASPICE framework that focuses on the systematic handling of change requests throughout the software development lifecycle. The primary objectives of SUP.10 include: II. Understanding SUP.10 Change Request Management A. Purpose and Outcomes of SUP.10 The primary purpose of SUP.10 is to ensure that change requests are managed and controlled throughout the software development lifecycle. Key outcomes of this process include: B. Key Base Practices To achieve these outcomes, ASPICE SUP.10 defines several base practices: C. Work Products and Their Significance SUP.10 defines several key work products that result from and support the change request management process: These work products play a crucial role in ensuring a systematic and traceable change request management process, facilitating communication among stakeholders, and providing evidence of compliance with ASPICE requirements. III. Implementing an Effective Change Request Management Strategy A. Developing a Robust Change Request Management Strategy A comprehensive strategy is the foundation of effective change request management. Key elements include: B. Establishing a Consistent Change Request Management Process Consistency is key to successful change request management: C. Defining Roles and Responsibilities Clear definition of roles is essential for efficient change request management: IV. Best Practices for SUP.10 Compliance A. Identifying and Recording Change Requests Effective identification and recording of change requests is crucial: B. Analyzing and Assessing Change Requests Thorough analysis is key to making informed decisions about change requests: C. Prioritizing and Approving Change Requests Effective prioritization and approval processes ensure that the most valuable changes are implemented: D. Implementing and Tracking Changes to Closure Proper implementation and tracking are essential for successful change management: V. Challenges and Solutions in Change Request Management A. Common Pitfalls in Automotive Software Change Management Several challenges can hinder effective change request management: B. Strategies for Overcoming Challenges To address these challenges, organizations can implement the following strategies: C. Case Studies of Successful SUP.10 Implementations Note:Actualcasestudieswouldbeincludedhere,butforthepurposesofthisoutline,I′llprovideagenericexample.Note:Actualcasestudieswouldbeincludedhere,butforthepurposesofthisoutline,I’llprovideagenericexample.Note:Actualcasestudieswouldbeincludedhere,butforthepurposesofthisoutline,I′llprovideagenericexample. Case Study: Major Automotive Supplier Streamlines Change Request Process A leading automotive supplier faced challenges with their change request management process, resulting in delays and quality issues. By implementing a standardized SUP.10 compliant process and investing in an integrated change management tool, they achieved: VI. Measuring and Improving Change Request Management Performance A. Key Performance Indicators (KPIs) for SUP.10 Effective measurement is crucial for continuous improvement. Key KPIs include: B. Continuous Improvement Strategies To drive ongoing enhancement of the change request management process: C. Tools and Technologies for Efficient Change Request Management Leveraging appropriate tools can significantly enhance the efficiency of change request management: VII. Future Trends in Automotive Change Management A. Impact of Emerging Technologies Emerging technologies are set to transform change request management in the automotive industry: B. Evolving Industry Standards and Regulations The regulatory landscape for automotive software development is continually evolving: C. Predictions for the Future of Change Request Management in Automotive Software Looking ahead, we can anticipate several trends in automotive change request management: Conclusion Mastering ASPICE SUP.10 Change Request Management is crucial for automotive companies striving to deliver high-quality, reliable, and safe software systems. By implementing robust change management strategies, leveraging data-driven approaches, and embracing emerging technologies, organizations can not only achieve ASPICE compliance but also position themselves at the forefront of automotive software development. The journey towards excellence in change request management is complex and ongoing. It requires a holistic approach that integrates change management activities with other development processes, fosters a culture of continuous improvement, and invests in advanced tools and technologies. Our company’s expertise in ASPICE consulting, combined with our innovative solutions, provides automotive manufacturers and suppliers with the guidance and tools needed to navigate these challenges successfully. By partnering with us, organizations can elevate their change request management processes, ensure ASPICE compliance, and ultimately deliver superior automotive software products that meet the demanding requirements of today’s and tomorrow’s vehicles.

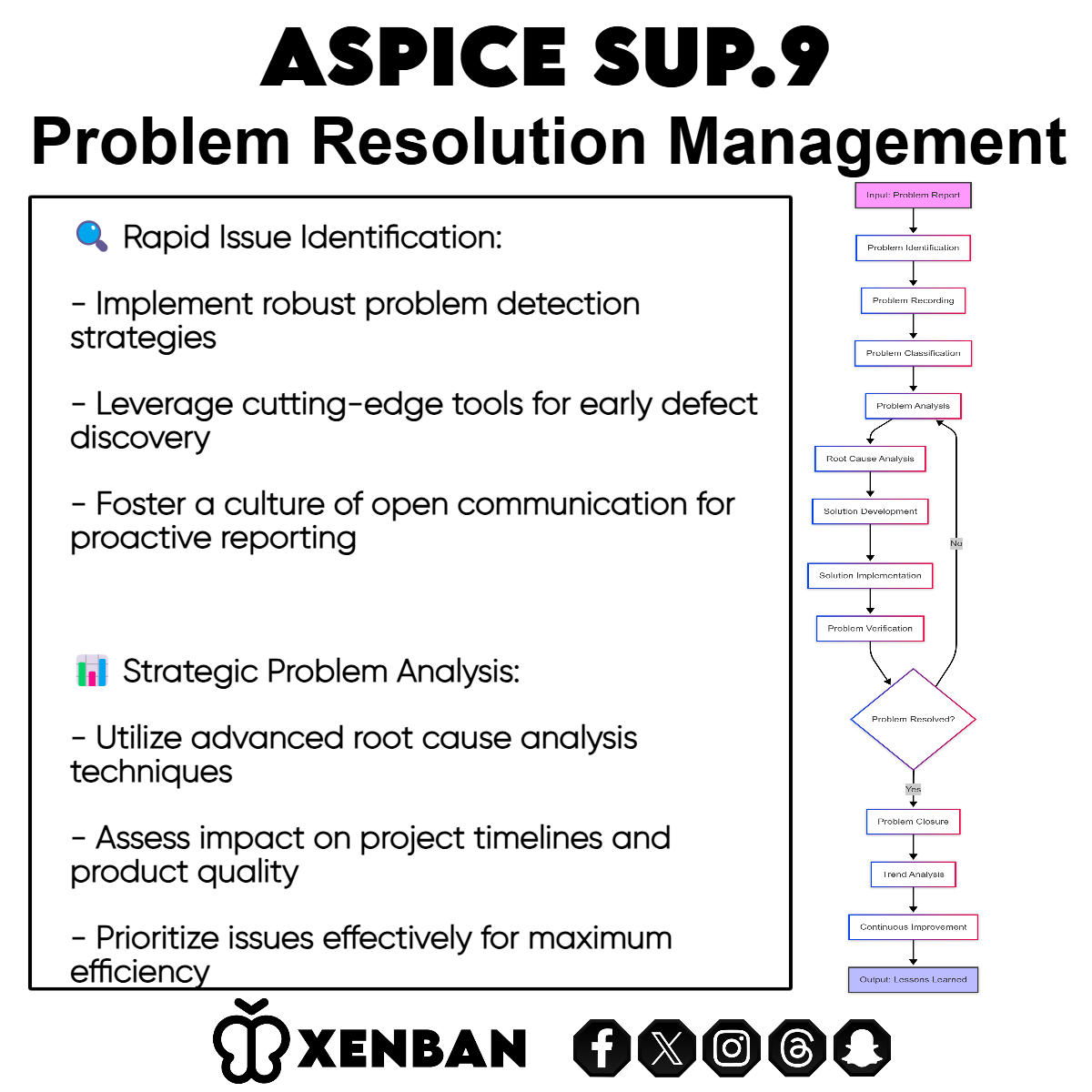

Executive Summary In the rapidly evolving automotive industry, software quality and reliability are paramount. ASPICE (Automotive Software Process Improvement and Capability Determination) SUP.9 Problem Resolution Management plays a crucial role in ensuring the delivery of high-quality automotive software systems. This whitepaper explores the intricacies of SUP.9, offering insights into its implementation, best practices, and the significant impact it can have on automotive software development projects. By mastering SUP.9, organizations can enhance their problem-solving capabilities, reduce development costs, and ultimately deliver superior products to market faster. 1. Introduction to ASPICE SUP.9 Problem Resolution Management 1.1 Definition and Purpose ASPICE SUP.9 Problem Resolution Management is a supporting process within the ASPICE framework that focuses on identifying, analyzing, and resolving problems encountered during the software development lifecycle. Its primary purpose is to ensure that all problems are systematically managed and resolved, minimizing their impact on project timelines, costs, and product quality. 1.2 Importance in Automotive Software Development In the automotive industry, where software complexity is continually increasing, effective problem resolution management is critical. SUP.9 helps organizations: 1.3 Key Components of SUP.9 The SUP.9 process consists of several key components: 2. Developing a Problem Resolution Management Strategy 2.1 Defining Problem Categories Establishing clear problem categories helps streamline the resolution process. Common categories in automotive software development include: 2.2 Establishing Roles and Responsibilities Clearly defined roles and responsibilities are essential for effective problem resolution management. Key roles typically include: 2.3 Selecting Appropriate Tools and Technologies Choosing the right tools can significantly enhance the efficiency of problem resolution management. Consider implementing: 2.4 Creating a Problem Status Model A well-defined problem status model helps track the progress of each issue through the resolution process. A typical model might include statuses such as: 3. Implementing Effective Problem Identification and Recording 3.1 Best Practices for Problem Identification To ensure comprehensive problem identification: 3.2 Techniques for Accurate Problem Recording Accurate problem recording is crucial for effective resolution. Key elements to include in problem reports are: 3.3 Ensuring Traceability and Unique Identification Maintaining traceability throughout the problem resolution process is essential for ASPICE compliance. Ensure that: 4. Problem Analysis and Impact Assessment 4.1 Root Cause Analysis Techniques Effective root cause analysis is critical for preventing recurrence of issues. Common techniques include: 4.2 Evaluating Problem Impact on Project and Product Assess the impact of each problem on: 4.3 Prioritization Strategies Develop a prioritization matrix based on factors such as: 5. Problem Resolution and Closure 5.1 Developing and Implementing Solutions When developing solutions: 5.2 Verification and Validation of Problem Resolution To ensure effective problem resolution: 5.3 Documenting and Communicating Resolutions Proper documentation and communication of problem resolutions are crucial for knowledge sharing and future reference. Include: 6. Continuous Improvement and Trend Analysis 6.1 Collecting and Analyzing Problem Data Regularly collect and analyze data on: 6.2 Identifying Recurring Issues and Patterns Use trend analysis to identify: 6.3 Implementing Preventive Measures Based on trend analysis: 7. Measuring Success: KPIs for Problem Resolution Management 7.1 Essential Metrics for SUP.9 Key Performance Indicators (KPIs) for problem resolution management include: 7.2 Interpreting and Acting on KPI Data Regularly review KPI data to: 7.3 Reporting and Visualization Techniques Effective reporting and visualization of problem resolution data can provide valuable insights. Consider using: Conclusion Implementing ASPICE SUP.9 Problem Resolution Management is crucial for automotive software development organizations aiming to deliver high-quality, reliable products. By following the best practices outlined in this whitepaper, companies can significantly enhance their problem-solving capabilities, reduce development costs, and improve overall product quality. Our expertise in ASPICE consulting and implementation can help your organization optimize its problem resolution management processes, ensuring compliance with industry standards while driving continuous improvement. By partnering with us, you can leverage our deep understanding of SUP.9 and the broader ASPICE framework to achieve excellence in automotive software development.

Executive Summary In the rapidly evolving automotive industry, software has become a critical component of vehicle functionality, safety, and user experience. As the complexity of automotive software systems increases, effective configuration management becomes paramount. This whitepaper explores ASPICE SUP.8 Configuration Management, a crucial process in the Automotive SPICE (ASPICE) framework, and its role in ensuring the quality, traceability, and reliability of automotive software development. We delve into the core components of ASPICE SUP.8, best practices for implementation, common challenges and their solutions, and future trends in configuration management. Through case studies and data-driven insights, we demonstrate how proper implementation of ASPICE SUP.8 can significantly enhance project efficiency, reduce errors, and ultimately lead to higher quality automotive software products. As industry leaders in ASPICE consulting, we provide a comprehensive guide to mastering configuration management in the automotive software development lifecycle, positioning your organization at the forefront of industry best practices. 1. Introduction to ASPICE SUP.8 Configuration Management 1.1 Definition and Purpose ASPICE SUP.8 Configuration Management is a support process within the Automotive SPICE framework that focuses on establishing and maintaining the integrity of work products throughout the software development lifecycle. It involves identifying, controlling, and tracking all configuration items, their versions, and their relationships. The primary purpose of SUP.8 is to ensure that: 1.2 Importance in Automotive Software Development In the automotive industry, where safety and reliability are paramount, configuration management plays a crucial role: 1.3 Key Outcomes of Effective Configuration Management When properly implemented, ASPICE SUP.8 leads to several positive outcomes: 2. Core Components of ASPICE SUP.8 2.1 Configuration Management Strategy The configuration management strategy outlines the overall approach, defining: 2.2 Configuration Item Identification This component involves: 2.3 Configuration Management System A robust Configuration Management System (CMS) should: 2.4 Branch Management Branch management strategies include: 2.5 Modification and Release Control This component focuses on: 2.6 Baseline Establishment Baseline establishment involves: 2.7 Configuration Status Reporting Regular status reporting includes: 3. Best Practices for Implementing ASPICE SUP.8 3.1 Developing a Robust Configuration Management Strategy 3.2 Effective Identification and Documentation of Configuration Items 3.3 Establishing and Maintaining a Configuration Management System 3.4 Implementing Branch Management for Parallel Developments 3.5 Controlling Modifications and Releases 3.6 Creating and Managing Baselines 3.7 Reporting and Verifying Configuration Status 4. Challenges and Solutions in Configuration Management 4.1 Common Pitfalls in ASPICE SUP.8 Implementation 4.2 Overcoming Resistance to Change 4.3 Balancing Flexibility and Control 4.4 Integrating Configuration Management with Other ASPICE Processes 5. The Future of Configuration Management in Automotive Software 5.1 Emerging Trends and Technologies 5.2 Impact of AI and Machine Learning on Configuration Management 5.3 Preparing for Future Challenges in Automotive Software Development 6. Case Studies: Successful ASPICE SUP.8 Implementations 6.1 Case Study 1: Improving Traceability in a Large-Scale Project A major automotive OEM implemented a new configuration management system, resulting in: 6.2 Case Study 2: Streamlining Release Management for a Tier 1 Supplier By adopting automated release processes, a Tier 1 supplier achieved: 6.3 Case Study 3: Enhancing Collaboration through Effective Branch Management A global development team implemented a new branching strategy, leading to: 7. Measuring the Success of Configuration Management 7.1 Key Performance Indicators for ASPICE SUP.8 7.2 Tools and Techniques for Monitoring Configuration Management Effectiveness 7.3 Continuous Improvement Strategies Conclusion Effective implementation of ASPICE SUP.8 Configuration Management is crucial for success in the increasingly complex world of automotive software development. By adopting best practices, leveraging emerging technologies, and continuously improving processes, organizations can enhance their software quality, reduce development costs, and maintain a competitive edge in the market. As demonstrated throughout this whitepaper, our company’s expertise in ASPICE consulting can guide you through the intricacies of implementing and optimizing your configuration management processes. We offer tailored solutions that align with your organization’s specific needs and goals, ensuring that you not only meet ASPICE requirements but also drive innovation and excellence in your automotive software development projects. By partnering with us, you gain access to industry-leading knowledge, proven methodologies, and cutting-edge tools that will position your organization at the forefront of automotive software development. Together, we can navigate the challenges of configuration management and unlock the full potential of your development processes, ultimately delivering superior software products that meet the demanding standards of the automotive industry.

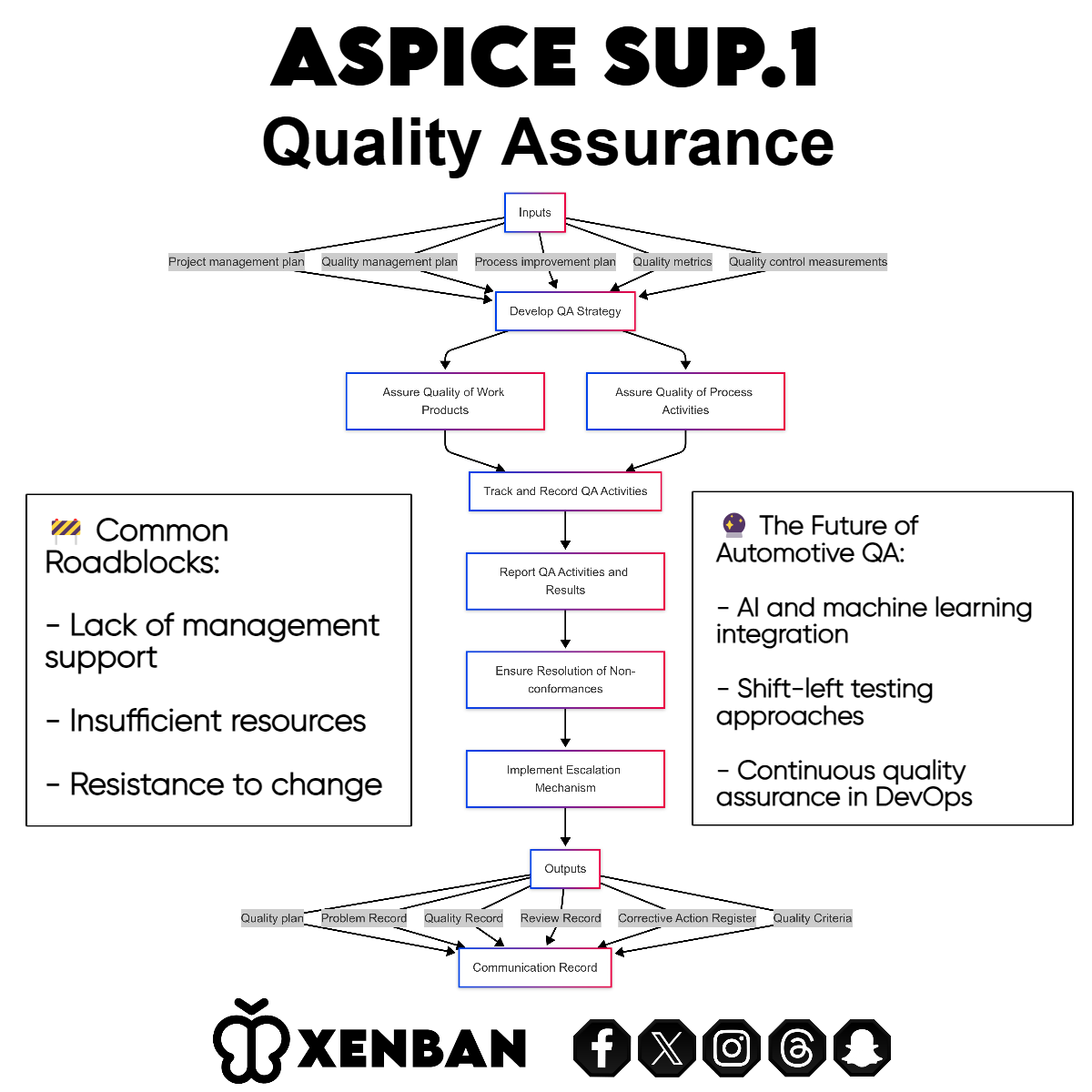

Executive Summary In the rapidly evolving automotive industry, software quality has become a critical differentiator. This whitepaper explores the Automotive SPICE (ASPICE) SUP.1 Quality Assurance process, a key component in ensuring the highest standards of software quality in automotive systems. We delve into the intricacies of SUP.1, its implementation challenges, best practices, and future trends. By mastering SUP.1, automotive companies can significantly enhance their software development processes, leading to improved product quality, reduced defects, and increased customer satisfaction. 1. Introduction to ASPICE and Quality Assurance What is ASPICE? Automotive SPICE (ASPICE) is a framework for designing and assessing software development processes in the automotive industry. It is based on the ISO/IEC 15504 standard and has been tailored specifically for the automotive sector. ASPICE provides a comprehensive set of process areas that cover the entire software development lifecycle, from requirements engineering to maintenance. The Importance of Quality Assurance in Automotive Software Development Quality assurance (QA) plays a crucial role in automotive software development due to the safety-critical nature of automotive systems. As vehicles become increasingly software-dependent, ensuring the reliability and safety of these systems is paramount. Effective QA processes help identify and mitigate risks early in the development cycle, reducing the likelihood of costly recalls and potential safety hazards. Overview of SUP.1 Quality Assurance Process The SUP.1 Quality Assurance process is a supporting process within the ASPICE framework. Its primary purpose is to provide independent and objective assurance that work products and processes comply with predefined provisions and plans. SUP.1 encompasses activities such as developing QA strategies, evaluating work products and processes, identifying and documenting non-conformances, and verifying their resolution. 2. Key Components of SUP.1 Quality Assurance Developing a Project Quality Assurance Strategy A robust QA strategy is the foundation of effective quality assurance. This strategy should outline: Establishing an Independent Quality Assurance Structure Independence is a crucial aspect of SUP.1. The QA function should be organizationally separate from the project management and development teams to ensure objective evaluation. This structure allows QA personnel to provide unbiased assessments and recommendations without undue influence from project pressures. Defining Quality Criteria for Work Products and Processes Clear, measurable quality criteria must be established for both work products and processes. These criteria should be: Assuring Quality of Work Products and Process Activities QA activities should be conducted throughout the development lifecycle. This includes: Tracking and Reporting Quality Assurance Activities Effective tracking and reporting mechanisms are essential for maintaining transparency and accountability in the QA process. This includes: 3. Implementing SUP.1 Quality Assurance in Practice Best Practices for Quality Assurance Planning Techniques for Effective Work Product and Process Evaluation Strategies for Non-conformance Resolution Implementing an Escalation Mechanism 4. Challenges and Solutions in SUP.1 Implementation Common Pitfalls in Quality Assurance Processes Strategies for Overcoming Implementation Challenges Case Studies of Successful SUP.1 Implementation (Note: Specific case studies would be included here, showcasing real-world examples of successful SUP.1 implementation and their positive impacts on automotive software development projects.) 5. Measuring and Improving Quality Assurance Effectiveness Key Performance Indicators for Quality Assurance Tools and Techniques for Quality Data Analysis Continuous Improvement Strategies for Quality Assurance Processes 6. The Future of Quality Assurance in Automotive Software Development Emerging Trends in Quality Assurance The Impact of New Technologies on Quality Assurance Processes Preparing for ASPICE 4.0 and Beyond 7. Conclusion: Elevating Quality Assurance for Automotive Excellence Implementing a robust SUP.1 Quality Assurance process is crucial for automotive companies aiming to deliver high-quality software systems. By following the best practices outlined in this whitepaper, organizations can enhance their development processes, reduce defects, and ultimately improve customer satisfaction. As the automotive industry continues to evolve, staying at the forefront of quality assurance practices will be essential for maintaining a competitive edge. Our expertise in ASPICE consulting can help organizations navigate the complexities of SUP.1 implementation, ensuring they meet the highest standards of quality in automotive software development. By partnering with us, companies can accelerate their journey towards ASPICE compliance and establish themselves as leaders in automotive software quality.

Executive Summary In the rapidly evolving automotive industry, ensuring product quality and reliability is paramount. The Automotive SPICE (ASPICE) framework provides a comprehensive approach to software process improvement, with VAL.1 Validation playing a crucial role in verifying that end products meet stakeholder requirements and perform as expected in their operational environments. This whitepaper explores the intricacies of VAL.1 Validation, offering insights into best practices, challenges, and innovative approaches that can help automotive organizations enhance their validation processes and achieve higher ASPICE maturity levels. By examining the key components of VAL.1, including process outcomes, implementation strategies, and performance measurement, we aim to provide a comprehensive guide for automotive software developers, quality assurance professionals, and executives. The paper also delves into emerging trends and future considerations in automotive validation, highlighting the importance of adapting validation processes to meet the demands of autonomous vehicles, electric powertrains, and cybersecurity concerns. Through this exploration, we position our company as a thought leader in ASPICE consulting, demonstrating our deep understanding of validation processes and our ability to guide organizations towards process improvement and product excellence. 1. Introduction to ASPICE and VAL.1 Validation 1.1 Overview of Automotive SPICE Automotive SPICE (ASPICE) is a framework for designing and assessing software development processes in the automotive industry. It is based on the ISO/IEC 15504 standard and has been tailored specifically for the automotive sector. ASPICE provides a common language and set of best practices for improving software development processes, ensuring quality, and reducing risks in automotive software projects. 1.2 The role of VAL.1 in the ASPICE framework VAL.1 Validation is a critical process within the ASPICE framework, focusing on ensuring that the developed product meets stakeholder expectations and functions correctly in its intended operational environment. It serves as a final quality gate, verifying that the software not only meets specified requirements but also satisfies the needs of end-users and other stakeholders. 1.3 Key objectives of the VAL.1 process The primary objectives of the VAL.1 process include: 2. Understanding VAL.1 Process Outcomes 2.1 Selecting validation measures The first step in the VAL.1 process is selecting appropriate validation measures. This involves: 2.2 Performing product validation Product validation involves executing the selected validation measures to verify that the product meets stakeholder needs and performs as expected in its intended environment. This may include: 2.3 Establishing traceability and consistency Traceability and consistency are crucial aspects of the VAL.1 process. This outcome focuses on: 2.4 Summarizing and communicating results The final outcome of the VAL.1 process involves: 3. Best Practices for Implementing VAL.1 3.1 Developing a robust validation strategy A well-defined validation strategy is essential for successful VAL.1 implementation. Best practices include: 3.2 Selecting appropriate validation techniques Choosing the right validation techniques is crucial for effective VAL.1 implementation. Consider: 3.3 Ensuring comprehensive stakeholder involvement Stakeholder involvement is key to successful validation. Best practices include: 3.4 Leveraging automation in validation processes Automation can significantly enhance the efficiency and effectiveness of validation processes: 4. Challenges in VAL.1 Implementation 4.1 Balancing validation thoroughness with time constraints One of the primary challenges in VAL.1 implementation is striking the right balance between comprehensive validation and project timelines. Strategies to address this include: 4.2 Managing complex system interactions Modern automotive systems often involve intricate interactions between various components and subsystems. Challenges in validating these complex interactions include: 4.3 Addressing non-functional requirements validation Validating non-functional requirements, such as performance, reliability, and security, can be particularly challenging. Approaches to overcome this include: 4.4 Maintaining consistency across validation activities Ensuring consistency in validation processes across different teams, projects, or organizational units can be challenging. Strategies to address this include: 5. Innovative Approaches to Product Validation 5.1 Model-based validation techniques Model-based validation is an emerging approach that can enhance the efficiency and effectiveness of validation processes: 5.2 AI-driven validation methods Artificial Intelligence (AI) and Machine Learning (ML) are increasingly being applied to automotive validation: 5.3 Virtual and augmented reality in validation processes Virtual Reality (VR) and Augmented Reality (AR) technologies offer new possibilities for product validation: 6. Measuring VAL.1 Process Capability 6.1 ASPICE capability levels for VAL.1 ASPICE defines six capability levels for process assessment, ranging from 0 (Incomplete) to 5 (Optimizing). For VAL.1, these levels can be interpreted as: 6.2 Key performance indicators for validation processes To assess the effectiveness of VAL.1 implementation, organizations can track various KPIs, including: 6.3 Continuous improvement strategies To drive continuous improvement in VAL.1 processes, organizations can: 7. Future Trends in Automotive Validation 7.1 Impact of autonomous vehicles on validation processes The rise of autonomous vehicles presents new challenges and opportunities for validation: 7.2 Cybersecurity considerations in validation As vehicles become more connected, cybersecurity validation becomes increasingly critical: 7.3 Adapting validation for electric and hybrid vehicles The shift towards electric and hybrid powertrains requires adjustments to validation processes: Conclusion: Elevating Product Quality Through Effective Validation Effective implementation of the VAL.1 Validation process is crucial for ensuring that automotive products meet stakeholder expectations and perform reliably in real-world conditions. As the industry evolves with new technologies and challenges, organizations must continually refine their validation processes to maintain high product quality and achieve higher ASPICE maturity levels. By adopting best practices, leveraging innovative techniques, and focusing on continuous improvement, automotive companies can enhance their validation capabilities and deliver superior products to the market. Key takeaways for organizations striving to excel in VAL.1 implementation include: Our ASPICE consulting services are designed to help organizations optimize their VAL.1 processes, providing expert guidance and tailored solutions to meet the unique challenges of each project. By partnering with us, automotive companies can accelerate their journey towards process maturity, enhance product quality, and gain a competitive edge in the rapidly evolving automotive landscape.

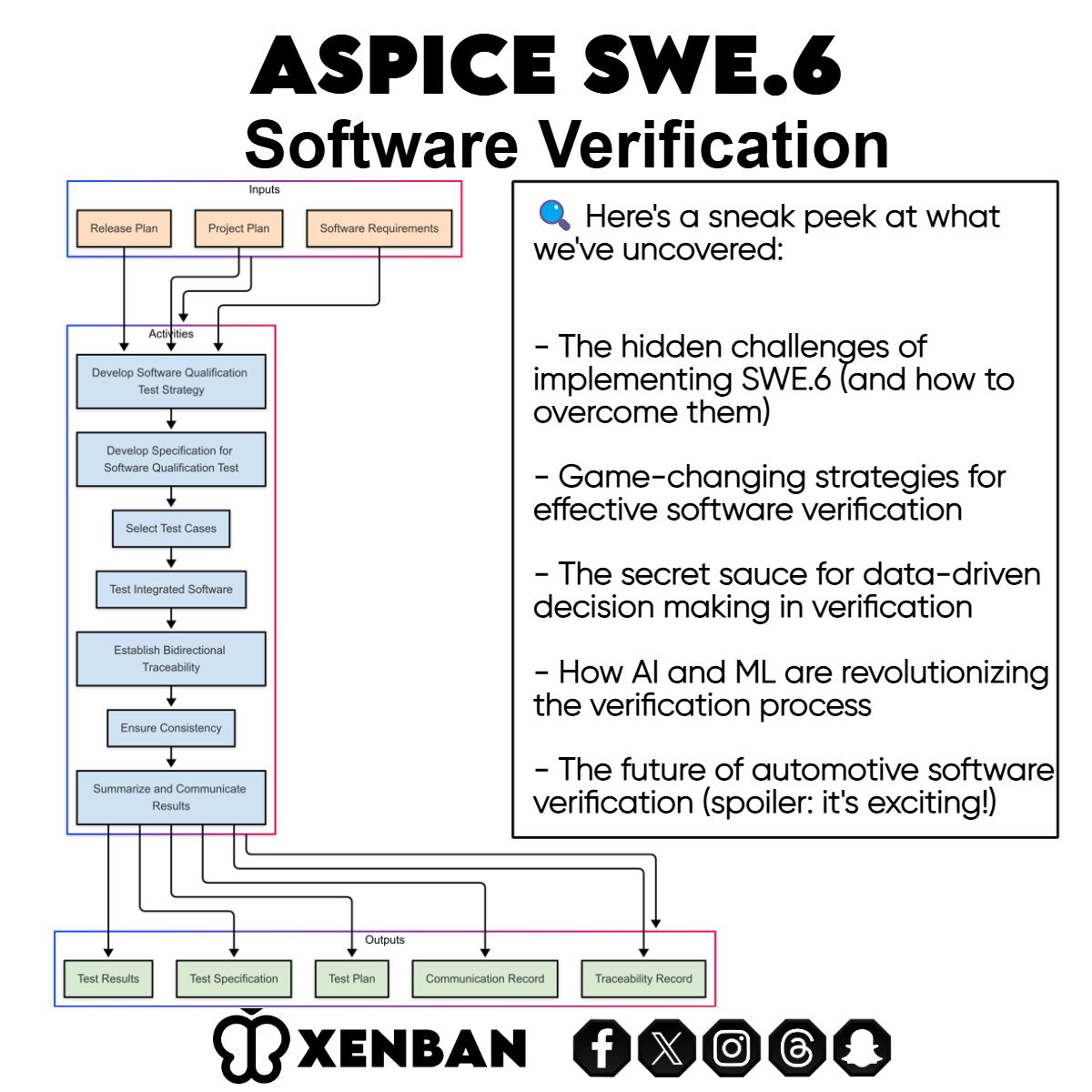

Executive Summary In the rapidly evolving automotive industry, software has become a critical component of vehicle functionality, safety, and user experience. As the complexity of automotive software systems increases, so does the need for robust verification processes. Automotive SPICE (ASPICE) SWE.6 Software Verification plays a pivotal role in ensuring the quality, reliability, and safety of automotive software. This whitepaper delves into the intricacies of ASPICE SWE.6, exploring its significance, implementation strategies, and best practices. We examine the challenges faced by automotive software developers and provide insights into overcoming these obstacles. By leveraging data-driven approaches and embracing emerging technologies, organizations can not only achieve ASPICE compliance but also elevate their software verification processes to new heights. Our company’s unique approach combines deep industry expertise with cutting-edge tools and methodologies, enabling automotive manufacturers and suppliers to navigate the complexities of ASPICE SWE.6 with confidence. Through this whitepaper, we aim to demonstrate our thought leadership in ASPICE consulting and showcase how our solutions address the critical challenges in software verification. I. Introduction to ASPICE and SWE.6 A. What is Automotive SPICE? Automotive SPICE (Software Process Improvement and Capability dEtermination) is a framework specifically designed for assessing and improving software development processes in the automotive industry. It is based on the ISO/IEC 15504 standard and has been adapted to meet the unique challenges and requirements of automotive software development. ASPICE provides a structured approach to process assessment and improvement, enabling organizations to: B. Overview of SWE.6 Software Verification Process SWE.6 Software Verification is a crucial process within the ASPICE framework, focusing on ensuring that the developed software meets its specified requirements. The primary objectives of SWE.6 include: C. Importance in Automotive Software Development The significance of SWE.6 in automotive software development cannot be overstated. As vehicles become increasingly software-dependent, the consequences of software failures can be severe, potentially impacting safety, performance, and user satisfaction. Effective software verification: II. The SWE.6 Process: A Deep Dive A. Purpose and Outcomes of SWE.6 The primary purpose of SWE.6 is to verify that the software implementation meets its specified requirements. Key outcomes of this process include: B. Key Base Practices To achieve these outcomes, ASPICE SWE.6 defines several base practices: C. Work Products and Their Significance SWE.6 defines several key work products that result from and support the verification process: These work products play a crucial role in ensuring a systematic and traceable verification process, facilitating communication among stakeholders, and providing evidence of compliance with ASPICE requirements. III. Implementing Effective Software Verification Strategies A. Developing a Robust Test Strategy A comprehensive test strategy is the foundation of effective software verification. Key elements include: B. Selecting Appropriate Test Cases Effective test case selection is crucial for comprehensive verification: C. Ensuring Traceability and Consistency Maintaining traceability and consistency throughout the verification process is essential: D. Best Practices for Test Execution and Reporting Efficient test execution and comprehensive reporting contribute to the success of the verification process: IV. Overcoming Common Challenges in SWE.6 Implementation A. Resource Allocation and Time Management Effective resource allocation and time management are critical for successful SWE.6 implementation: B. Handling Complex Software Systems Modern automotive software systems are increasingly complex, presenting unique verification challenges: C. Ensuring Comprehensive Test Coverage Achieving adequate test coverage is essential for thorough software verification: D. Managing Changes and Regression Testing Effective change management and regression testing are crucial in the dynamic automotive software development environment: V. Data-Driven Decision Making in Software Verification A. Leveraging Metrics for Process Improvement Data-driven decision making is crucial for continuous improvement in software verification: B. Analyzing Test Results for Quality Insights In-depth analysis of test results can provide valuable insights into software quality: C. Predictive Analytics for Defect Prevention Leveraging predictive analytics can help prevent defects and optimize the verification process: VI. The Future of Software Verification in Automotive A. Emerging Trends and Technologies The automotive software verification landscape is evolving rapidly, driven by technological advancements: B. Impact of AI and Machine Learning AI and ML are poised to revolutionize software verification in the automotive industry: C. Preparing for ASPICE 4.0 and Beyond As the automotive industry evolves, so too will the ASPICE framework: VII. Achieving ASPICE Compliance: A Holistic Approach A. Integrating SWE.6 with Other ASPICE Processes Effective implementation of SWE.6 requires integration with other ASPICE processes: B. Building a Culture of Quality and Continuous Improvement Fostering a culture that prioritizes quality and continuous improvement is essential for successful ASPICE implementation: C. Training and Skill Development for Effective Implementation Investing in training and skill development is crucial for effective SWE.6 implementation: Conclusion Mastering ASPICE SWE.6 Software Verification is crucial for automotive companies striving to deliver high-quality, reliable, and safe software systems. By implementing robust verification strategies, leveraging data-driven approaches, and embracing emerging technologies, organizations can not only achieve ASPICE compliance but also position themselves at the forefront of automotive software development. The journey towards excellence in software verification is complex and ongoing. It requires a holistic approach that integrates verification activities with other development processes, fosters a culture of quality, and invests in continuous skill development. As the automotive industry continues to evolve, so too must our approaches to software verification. Our company’s expertise in ASPICE consulting, combined with our innovative solutions, provides automotive manufacturers and suppliers with the guidance and tools needed to navigate these challenges successfully. By partnering with us, organizations can elevate their software verification processes, ensure ASPICE compliance, and ultimately deliver superior automotive software products that meet the demanding requirements of today’s and tomorrow’s vehicles.

Executive Summary In the rapidly evolving automotive industry, software quality and reliability are paramount. Automotive SPICE (ASPICE) has emerged as a crucial framework for ensuring software development processes meet the stringent requirements of the automotive sector. Within this framework, the Software Engineering process SWE.5, focusing on Software Component Verification and Integration Verification, plays a pivotal role in delivering high-quality, reliable software systems. This whitepaper delves into the intricacies of SWE.5, exploring its significance, implementation strategies, challenges, and best practices. By mastering SWE.5, automotive companies can significantly enhance their software quality, reduce defects, and improve overall project success rates. Our expertise in ASPICE consulting, particularly in SWE.5 implementation, positions us uniquely to guide automotive software developers through this critical process, ensuring compliance and driving innovation in the industry. 1. Introduction to ASPICE and SWE.5 1.1 Overview of Automotive SPICE Automotive SPICE (ASPICE) is a framework specifically designed for assessing and improving software development processes in the automotive industry. It is based on the ISO/IEC 15504 standard and has been tailored to address the unique challenges and requirements of automotive software development. ASPICE defines a set of process assessment models and a measurement framework that allows organizations to evaluate their software development capabilities. It covers various aspects of software development, from project management to engineering and support processes. 1.2 The role of SWE.5 in the software development lifecycle SWE.5, or Software Component Verification and Integration Verification, is a crucial process within the ASPICE framework. It focuses on ensuring that individual software components and their integration meet specified requirements and function correctly as a system. The SWE.5 process is typically executed after the software components have been developed (SWE.3) and before the final software qualification testing (SWE.6). It serves as a critical quality gate, verifying that components work correctly both individually and when integrated. 1.3 Importance of component verification and integration verification Component verification and integration verification are essential for several reasons: 2. Understanding SWE.5: Software Component Verification and Integration Verification 2.1 Defining software components and integration In the context of ASPICE and SWE.5: 2.2 Key objectives of SWE.5 The primary objectives of SWE.5 are: 2.3 Base practices in SWE.5 ASPICE defines several base practices for SWE.5, including: 3. Implementing SWE.5 in Automotive Software Development 3.1 Developing a software integration strategy A robust software integration strategy is crucial for successful SWE.5 implementation. This strategy should: 3.2 Creating effective test specifications Test specifications for both component and integration verification should: 3.3 Performing software integration tests Integration tests should be performed systematically, following the integration strategy. Key aspects include: 3.4 Ensuring traceability and consistency Maintaining traceability and consistency is crucial in SWE.5. This involves: 4. Challenges and Best Practices in SWE.5 Implementation 4.1 Common challenges in software component verification Some common challenges include: 4.2 Strategies for effective integration verification Effective strategies include: 4.3 Tools and techniques for streamlining SWE.5 processes Various tools can aid in SWE.5 implementation: 5. The Impact of SWE.5 on Software Quality and Project Success 5.1 Measuring the effectiveness of SWE.5 implementation Key metrics for assessing SWE.5 effectiveness include: 5.2 Case studies: Successful SWE.5 adoption in automotive projects (Note: Specific case studies would be included here, showcasing successful implementations of SWE.5 in real automotive projects.) 5.3 ROI of robust component and integration verification Implementing robust SWE.5 processes can lead to: 6. Future Trends in Software Verification for Automotive Systems 6.1 Emerging technologies in software verification Emerging trends include: 6.2 The role of AI and machine learning in SWE.5 AI and machine learning are poised to revolutionize SWE.5 processes through: 6.3 Preparing for future ASPICE updates To stay ahead, organizations should: 7. Our Approach to SWE.5 Consulting 7.1 Our methodology for SWE.5 implementation Our approach includes: 7.2 How we address common SWE.5 challenges We offer: 7.3 Success stories from our clients (Note: This section would include anonymized success stories from clients who have benefited from our SWE.5 consulting services.) Conclusion Mastering SWE.5 is crucial for automotive companies aiming to develop high-quality, reliable software systems. By implementing robust component verification and integration verification processes, organizations can significantly reduce defects, improve product quality, and enhance overall project success rates. Our expertise in ASPICE consulting, particularly in SWE.5 implementation, positions us as an ideal partner for automotive companies looking to excel in this critical area. We offer comprehensive solutions that not only ensure compliance with ASPICE standards but also drive innovation and efficiency in software development processes. As the automotive industry continues to evolve, with software becoming an increasingly critical component of vehicles, the importance of effective SWE.5 implementation will only grow. By partnering with us, automotive companies can stay ahead of the curve, delivering superior software products that meet the stringent quality and safety requirements of the industry.

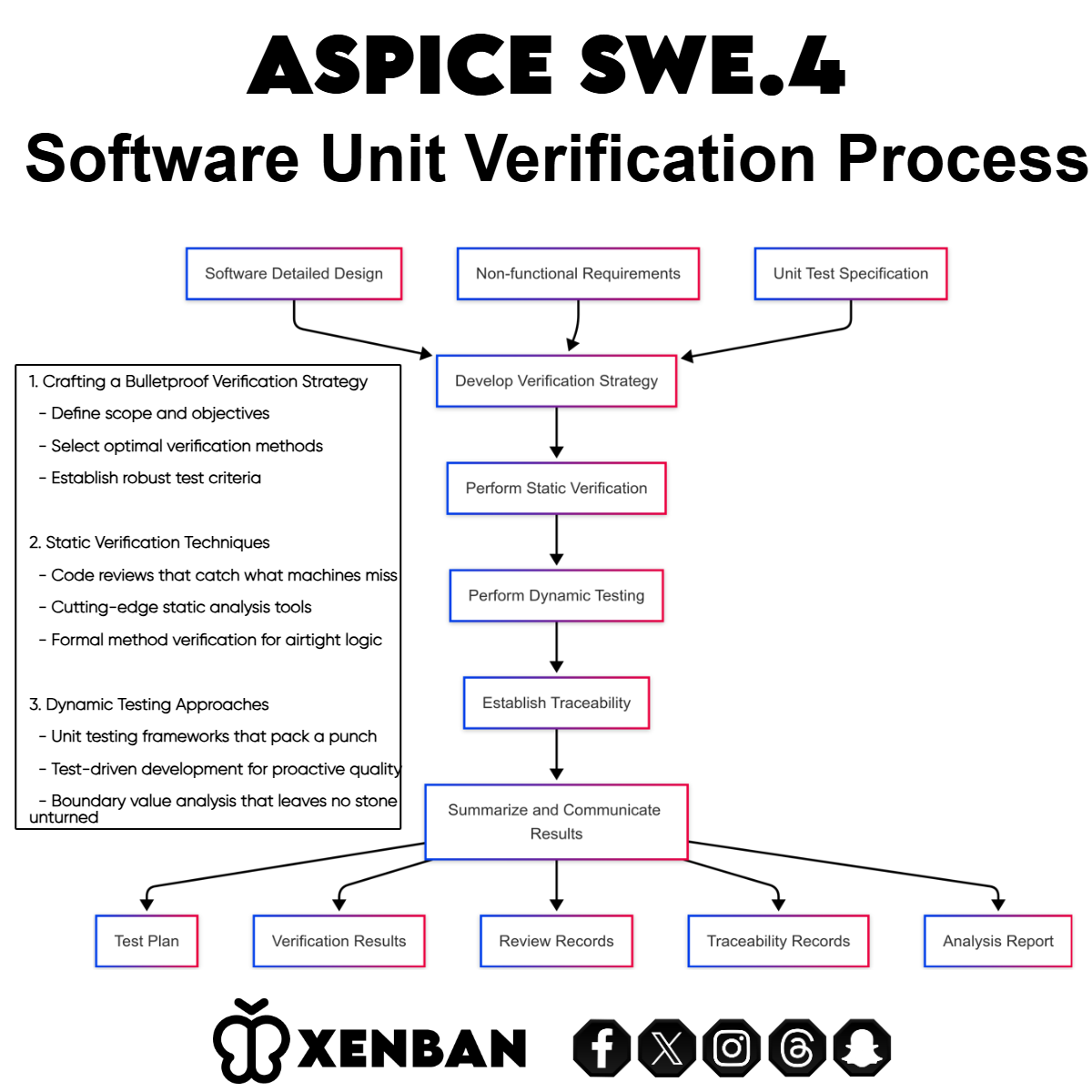

Executive Summary In the rapidly evolving automotive industry, software quality and reliability are paramount. The Automotive SPICE (ASPICE) framework, specifically the Software Unit Verification (SWE.4) process, plays a crucial role in ensuring that software units meet stringent quality standards. This whitepaper delves into the intricacies of SWE.4, offering comprehensive insights into its implementation, best practices, and impact on overall software quality. We explore how SWE.4 fits into the broader ASPICE framework, detailing its key components and outcomes. Through an in-depth analysis of verification strategies, testing methodologies, and performance metrics, we provide a roadmap for automotive software developers to enhance their unit verification processes. Additionally, we examine emerging trends and technologies that are shaping the future of software unit verification. By the end of this whitepaper, readers will gain a thorough understanding of how to leverage SWE.4 to improve software quality, reduce defects, and ultimately deliver more reliable automotive software systems. 1. Introduction to ASPICE SWE.4 1.1 Definition and Purpose Software Unit Verification (SWE.4) is a critical process within the Automotive SPICE framework, designed to ensure that individual software units comply with specified requirements. The primary purpose of SWE.4 is to verify that each software unit, the smallest testable component of a software system, functions correctly in isolation before integration into larger systems. 1.2 Importance in Automotive Software Development In the automotive industry, where software failures can have severe consequences, SWE.4 plays a vital role in: 1.3 Key Outcomes of SWE.4 The successful implementation of SWE.4 results in: 2. The SWE.4 Process in Detail 2.1 Developing a Verification Strategy A robust verification strategy is the foundation of effective SWE.4 implementation. This strategy should: 2.2 Criteria for Unit Verification Effective unit verification relies on well-defined criteria, including: 2.3 Static Verification Techniques Static verification involves analyzing the software unit without executing it. Key techniques include: 2.4 Dynamic Testing Approaches Dynamic testing involves executing the software unit to observe its behavior. Common approaches include: 3. Best Practices in Software Unit Verification 3.1 Automated Testing Frameworks Implementing automated testing frameworks is crucial for efficient and consistent unit verification. Best practices include: 3.2 Code Review Methodologies Effective code reviews complement automated testing by: 3.3 Continuous Integration and Verification Integrating SWE.4 into a continuous integration (CI) pipeline offers several benefits: 4. Challenges and Solutions in Implementing SWE.4 4.1 Common Pitfalls in Unit Verification Some challenges in implementing SWE.4 include: 4.2 Strategies for Overcoming Implementation Hurdles To address these challenges, organizations can: 4.3 Case Studies: Successful SWE.4 Implementations (Note: Specific case studies would be included here, showcasing real-world examples of successful SWE.4 implementations and their impact on software quality and development efficiency.) 5. Measuring the Effectiveness of SWE.4 5.1 Key Performance Indicators To assess the effectiveness of SWE.4 implementation, organizations should track: 5.2 Metrics for Unit Verification Quality Key metrics for evaluating the quality of unit verification include: 5.3 ROI of Robust Unit Verification Processes Implementing a comprehensive SWE.4 process can yield significant returns: 6. Future Trends in Software Unit Verification 6.1 AI and Machine Learning in Verification Emerging AI and ML technologies are poised to revolutionize unit verification by: 6.2 Shift-Left Testing Approaches The trend towards “shift-left” testing emphasizes: 6.3 Integration with DevOps Practices The integration of SWE.4 with DevOps practices is leading to: 7. Conclusion: Elevating Software Quality through SWE.4 7.1 Recap of Key Points The ASPICE SWE.4 process is fundamental to ensuring high-quality software in the automotive industry. By implementing robust unit verification strategies, organizations can significantly reduce defects, improve code quality, and enhance overall software reliability. 7.2 The Role of SWE.4 in Overall Software Quality SWE.4 serves as a critical foundation for software quality, enabling: 7.3 How Our Consulting Services Enhance SWE.4 Implementation Our expert consulting services offer: By partnering with us, automotive software developers can optimize their SWE.4 processes, ensuring compliance with ASPICE standards and delivering high-quality, reliable software solutions that meet the demanding requirements of the automotive industry.

Executive Summary The Software Detailed Design and Unit Construction (SWE.3) process is a critical component of Automotive SPICE (ASPICE), providing a framework for creating evaluated detailed designs for software components and producing high-quality software units. This whitepaper explores the key aspects of SWE.3, its implementation challenges, and best practices for automotive software development. By mastering this process, organizations can enhance their software quality, reduce development costs, and improve their competitive edge in the automotive industry. 1. Introduction to ASPICE SWE.3 1.1 Overview of Automotive SPICE Automotive SPICE is a framework designed to assess and enhance software development processes within the automotive industry. It provides a standardized approach to evaluating and improving software engineering practices, ensuring high-quality, reliable, and safe automotive software systems. 1.2 The role of SWE.3 in the software development lifecycle SWE.3 plays a crucial role in bridging the gap between high-level software architectural design and the actual implementation of software units. It focuses on creating detailed designs that serve as the foundation for code implementation and unit testing. 1.3 Key objectives and outcomes of SWE.3 The primary objectives of SWE.3 include: 2. The SWE.3 Process in Detail 2.1 Developing software detailed design The detailed design process involves creating a comprehensive description of each software component, including its internal structure, algorithms, and data structures. This design should be sufficiently detailed to guide the implementation and testing phases. 2.2 Defining interfaces of software units Proper interface definition is crucial for ensuring seamless integration of software units. This includes specifying: 2.3 Describing dynamic behavior The dynamic behavior of software units, including their interactions and state changes, must be documented. This may involve the use of state diagrams, sequence diagrams, or other appropriate modeling techniques. 2.4 Evaluating software detailed design The detailed design should be evaluated for: 2.5 Establishing bidirectional traceability Traceability must be established between: 2.6 Ensuring consistency Consistency checks should be performed to ensure alignment between: 2.7 Communicating agreed software detailed design The finalized detailed design must be effectively communicated to all relevant stakeholders, ensuring a shared understanding of the software structure and functionality. 2.8 Developing software units Based on the detailed design, software units are implemented, adhering to coding standards and best practices. 3. Implementing SWE.3: Challenges and Solutions 3.1 Common obstacles in SWE.3 implementation Organizations often face challenges in: 3.2 Strategies for overcoming challenges To address these challenges, organizations can: 3.3 Tools and techniques for effective SWE.3 execution Leveraging appropriate tools can significantly enhance SWE.3 implementation: 4. Best Practices for SWE.3 Compliance 4.1 Aligning detailed design with architectural design Ensure that the detailed design accurately reflects and refines the high-level architectural decisions, maintaining consistency throughout the development process. 4.2 Optimizing interface documentation Provide comprehensive interface specifications, including all necessary details for proper implementation and testing. This facilitates better integration and reduces potential errors during the development process. 4.3 Enhancing traceability and consistency Implement automated traceability tools to maintain links between requirements, design elements, and code. Regularly perform consistency checks to identify and resolve any discrepancies. 4.4 Leveraging automation in the SWE.3 process Utilize automated code generation tools, where appropriate, to ensure consistency between the detailed design and the implemented code. This can help reduce errors and improve development efficiency. 5. SWE.3 and Safety-Critical Software Development 5.1 Meeting ISO 26262 requirements through SWE.3 SWE.3 plays a crucial role in meeting the requirements of ISO 26262 for functional safety in automotive software. It provides a structured approach to designing and implementing software components that can be rigorously verified and validated. 5.2 Balancing detail and flexibility in safety-critical designs For safety-critical software, the level of design detail must be carefully balanced to ensure comprehensive coverage of safety requirements while maintaining flexibility for implementation. 5.3 Integrating SWE.3 with other ASPICE processes for comprehensive safety assurance SWE.3 should be tightly integrated with other ASPICE processes, such as Software Requirements Analysis (SWE.1) and Software Unit Verification (SWE.4), to create a cohesive safety-focused development lifecycle. 6. Measuring SWE.3 Process Maturity 6.1 Key performance indicators for SWE.3 Establish metrics to assess the effectiveness of the SWE.3 process, such as: 6.2 Assessing and improving SWE.3 capability levels Regularly assess the maturity of the SWE.3 process using the ASPICE capability levels, ranging from Level 0 (Incomplete) to Level 5 (Innovating). Identify areas for improvement and implement targeted enhancement initiatives. 6.3 Continuous improvement strategies for SWE.3 Implement a feedback loop to continuously refine the SWE.3 process based on: 7. Future Trends and Innovations in Software Detailed Design 7.1 Impact of model-based development on SWE.3 Model-based development approaches are increasingly being adopted in automotive software development. These methods can enhance the SWE.3 process by providing more precise and verifiable design representations. 7.2 Artificial intelligence and machine learning in detailed design AI and ML technologies are beginning to play a role in software design, potentially assisting in: 7.3 Adapting SWE.3 for agile and DevOps environments As automotive software development embraces more agile and DevOps practices, SWE.3 processes need to evolve to support: Conclusion The SWE.3 Software Detailed Design and Unit Construction process is fundamental to achieving high-quality, reliable automotive software. By mastering this process, organizations can significantly enhance their software development capabilities, ensuring consistency, traceability, and compliance with industry standards. As the automotive industry continues to evolve towards software-defined vehicles, the importance of robust detailed design processes will only grow. Our company’s expertise in ASPICE consulting, combined with our cutting-edge tools for process automation and traceability, positions us uniquely to help automotive companies excel in SWE.3 implementation and achieve their software quality goals.

Executive Summary This whitepaper explores the ASPICE SWE.2 Software Architectural Design process, a critical component in automotive software development. We delve into the key aspects of SWE.2, best practices for implementation, common challenges, and its role within the broader ASPICE framework. By understanding and effectively implementing SWE.2, organizations can significantly enhance their software quality, compliance, and innovation in the automotive industry. 1. Introduction to ASPICE and SWE.2 What is ASPICE? Automotive SPICE (ASPICE) is a framework for assessing and improving software development processes in the automotive industry. It provides a standardized approach to evaluate the capability of software suppliers and ensure high-quality software development practices. Overview of the SWE.2 process The SWE.2 Software Architectural Design process is a crucial part of ASPICE, focusing on creating a comprehensive software architecture that meets the specified requirements. It involves developing a high-level design that outlines the structure, components, and interfaces of the software system. Importance in automotive software development In the rapidly evolving automotive industry, where software plays an increasingly critical role, SWE.2 is essential for: 2. Key Components of SWE.2 Software Architectural Design Developing the software architectural design The software architectural design process involves creating a high-level structure of the software system, defining its major components and their relationships. This includes: Allocating software requirements Requirements allocation is the process of mapping software requirements to specific components or elements of the architectural design. This ensures that: Defining interfaces of software elements Interface definition is crucial for ensuring proper communication and integration between software components. This involves: Describing dynamic behavior The dynamic behavior of the software system describes how components interact over time and respond to various stimuli. This includes: Defining resource consumption objectives Resource consumption objectives are essential for ensuring that the software system operates efficiently within the constraints of the target hardware. This involves: 3. Best Practices for Implementing SWE.2 Utilizing appropriate design tools Selecting and using the right tools can significantly enhance the efficiency and effectiveness of the architectural design process. Key considerations include: Creating clear and consistent documentation Comprehensive and well-structured documentation is crucial for effective communication and maintenance of the software architecture. Best practices include: Ensuring traceability between requirements and design elements Traceability is essential for demonstrating that all requirements are addressed in the design and for managing the impact of changes. Effective traceability practices include: Evaluating alternative architectures Considering multiple architectural options helps in making informed decisions and optimizing the design. This process should include: Communicating the agreed design to stakeholders Effective communication of the architectural design is crucial for ensuring alignment and buy-in from all stakeholders. This involves: 4. Challenges and Solutions in SWE.2 Implementation Common pitfalls in software architectural design Several challenges can hinder effective implementation of SWE.2: Strategies for overcoming challenges To address these challenges, organizations can: Case studies of successful SWE.2 implementations $$Note: Specific case studies would be included here, highlighting real-world examples of successful SWE.2 implementations in automotive software development projects.$$ 5. The Role of SWE.2 in the Broader ASPICE Framework Interconnections with other ASPICE processes SWE.2 is closely related to several other ASPICE processes, including: Understanding these relationships is crucial for effective implementation of SWE.2 and overall process improvement. Impact on overall software quality and compliance Effective implementation of SWE.2 contributes significantly to: Future trends in automotive software architecture Emerging trends that will shape the future of automotive software architecture include: 6. Measuring Success: KPIs for SWE.2 Process Effectiveness Quantitative metrics for assessing architectural design quality Key metrics for evaluating the effectiveness of SWE.2 implementation include: Qualitative indicators of successful implementation Qualitative aspects to consider include: Continuous improvement strategies To ensure ongoing enhancement of the SWE.2 process: 7. Tools and Technologies Supporting SWE.2 Overview of popular software architecture visualization tools Several tools can aid in the visualization and management of software architectures: Emerging technologies in architectural design Emerging technologies that can enhance the SWE.2 process include: Selecting the right tools for your organization Factors to consider when choosing tools include: Conclusion: Driving Innovation Through Effective Software Architecture Effective implementation of the ASPICE SWE.2 Software Architectural Design process is crucial for success in the rapidly evolving automotive software industry. By adopting best practices, overcoming common challenges, and leveraging appropriate tools and technologies, organizations can create robust, scalable, and innovative software architectures that meet the demanding requirements of modern vehicles. As the complexity of automotive software continues to grow, the importance of a well-structured and thoroughly documented software architecture cannot be overstated. It serves as the foundation for all subsequent development activities and plays a critical role in ensuring the safety, reliability, and performance of automotive systems. By partnering with experienced ASPICE consultants, organizations can navigate the complexities of SWE.2 implementation, optimize their software development processes, and position themselves at the forefront of automotive innovation. With a solid architectural foundation, automotive companies can confidently tackle the challenges of tomorrow’s software-defined vehicles and drive the future of mobility.