In the rapidly evolving automotive industry, ensuring the safety of increasingly complex electronic systems is paramount. ISO 26262, the international standard for functional safety in road vehicles, provides a comprehensive framework for addressing potential hazards caused by malfunctioning electrical and electronic systems. At the core of this standard lies the concept of Safety Goals, which are crucial for ensuring the reliability and safety of modern vehicles.

Understanding ISO 26262 and Safety Goals

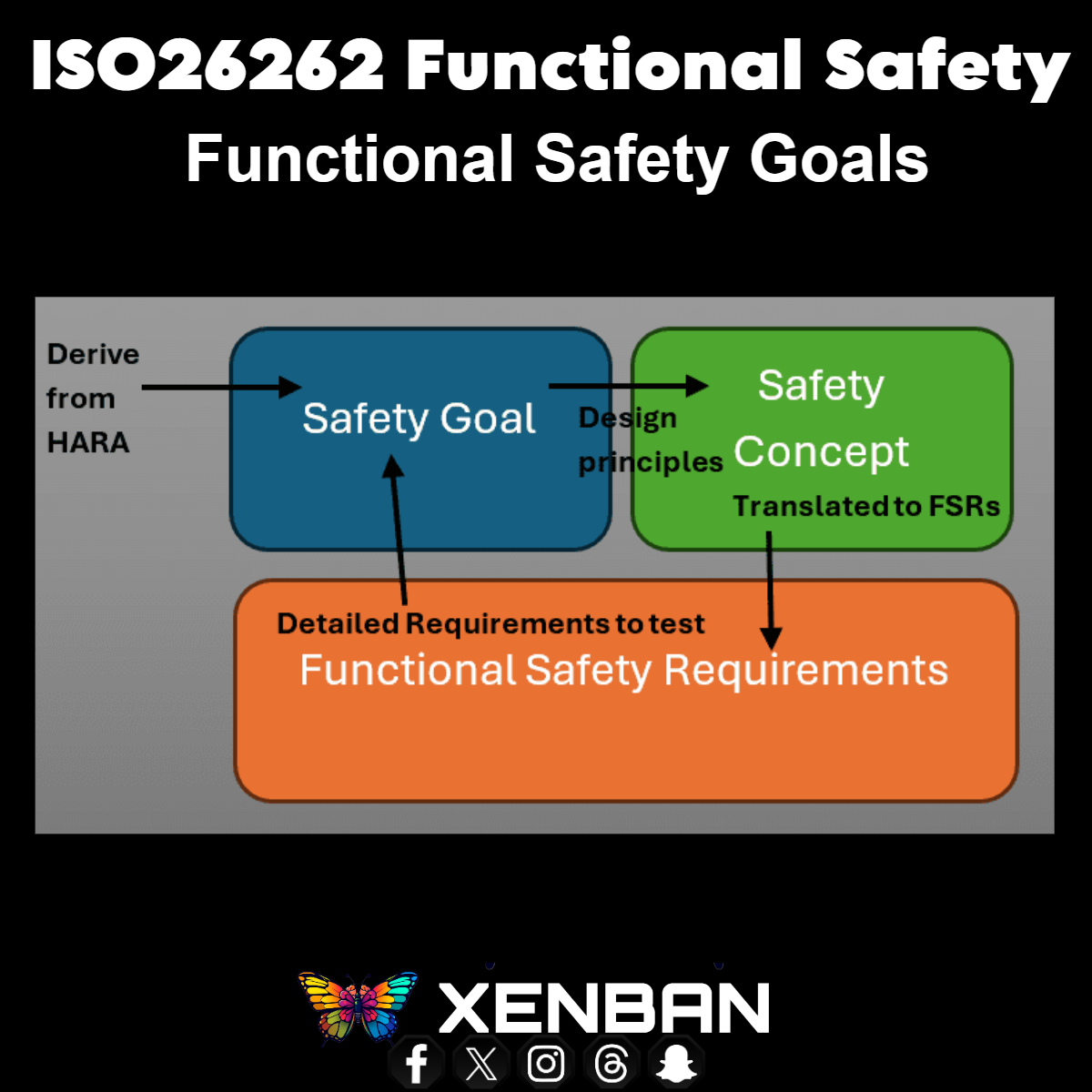

ISO 26262, titled “Road vehicles – Functional safety,” is an adaptation of the Functional Safety standard IEC 61508 specifically tailored for automotive electric/electronic systems. This standard addresses potential hazards throughout a vehicle’s lifecycle, with Safety Goals serving as the foundation of the framework.Safety Goals are top-level safety requirements assigned to a system to reduce the risk of hazardous events to a tolerable level. They are critical because they:

- Define overall safety objectives for vehicle systems

- Guide the development of detailed safety requirements

- Serve as benchmarks for safety validation and verification processes

The Process of Developing Safety Goals

1. Hazard Analysis and Risk Assessment (HARA)

Before defining Safety Goals, a comprehensive HARA must be conducted to identify potential hazards and assess their risk levels.

2. Identifying Hazardous Events

Hazardous events are combinations of vehicle-level hazards and operational situations that could lead to accidents if not controlled.

3. Assigning Automotive Safety Integrity Levels (ASIL)

Each hazardous event is assigned an ASIL, ranging from A (lowest risk) to D (highest risk), based on:

- Severity of potential harm

- Probability of exposure

- Controllability by the driver

4. Formulating Safety Goals

For each identified hazardous event, a corresponding Safety Goal is formulated. These goals should be:

- Expressed as functional objectives, not technical solutions

- Clear and concise

- Traceable to the hazardous events they address

Characteristics of Effective Safety Goals

To ensure compliance with ISO 26262, Safety Goals should be:

- Specific and measurable

- Directly addressing identified risks

- Achievable within system constraints

- Relevant to overall vehicle safety

- Time-bound, considering the vehicle’s lifecycle

The Role of Safety Goals in Development

Safety Goals play a crucial role throughout the automotive development process:

- Concept Phase: Initially defined, setting the direction for safety-related activities

- System Design: Guide the development of functional safety requirements and influence system architecture decisions

- Implementation and Testing: Serve as high-level criteria for validating and verifying safety measures

- Production and Operation: Remain relevant during production, ensuring manufacturing processes maintain intended safety levels

Challenges in Developing Safety Goals

Creating effective Safety Goals can be challenging due to:

- Increasing complexity of automotive systems

- Interdependencies between various vehicle subsystems

- Rapid technological advancements

- Balancing safety requirements with performance and cost considerations

Xenban’s Expertise in Functional Safety

As the automotive industry continues to evolve, companies like Xenban play a crucial role in ensuring functional safety compliance. Xenban specializes in providing engineering services and IT solutions to digitally transform products and businesses, with a particular focus on functional safety in automotive design.Xenban’s team of highly skilled Functional Safety Engineers are experts in ISO 26262 compliance and ASPICE (Automotive Software Process Improvement and Capability Determination) standards. They work closely with cross-functional teams to define safety requirements, conduct safety analyses, and develop comprehensive safety documentation.Key services offered by Xenban in the realm of functional safety include:

- Conducting Hazard Analysis and Risk Assessments (HARA)

- Developing and implementing Safety Goals

- Creating functional safety concepts and technical safety concepts

- Performing safety analyses (FMEA, FTA, FMEDA)

- Developing safety cases and safety argumentation

- Providing training and consultation on ISO 26262 compliance

By leveraging Xenban’s expertise, automotive manufacturers can ensure that their vehicles meet the highest safety standards while navigating the complexities of modern automotive technology.

Conclusion

Safety Goals are the cornerstone of functional safety in automotive design under ISO 26262. They provide a clear, high-level framework for ensuring that vehicles meet stringent safety standards in an increasingly complex technological landscape. As the automotive world continues to evolve, with the rise of electric and autonomous vehicles, the importance of well-defined Safety Goals will only grow.

Companies like Xenban are at the forefront of this evolution, offering specialized services to help automotive manufacturers navigate the challenges of functional safety. By partnering with experts in the field, automotive companies can not only comply with international standards but also build safer, more reliable vehicles that inspire consumer confidence and drive innovation in the industry.

In this rapidly changing landscape, the role of functional safety experts like those at Xenban will be crucial in creating a future where automotive technology and safety go hand in hand, ensuring that the vehicles of tomorrow are not only more advanced but also safer than ever before.