🔋 Ensuring Functional Safety in Battery Management Systems (BMS): Key Requirements 🔋

With the rise of electric vehicles (EVs) and energy storage systems, the functional safety of Battery Management Systems (BMS) is paramount. Here’s a detailed overview of essential safety requirements to enhance BMS reliability and performance:

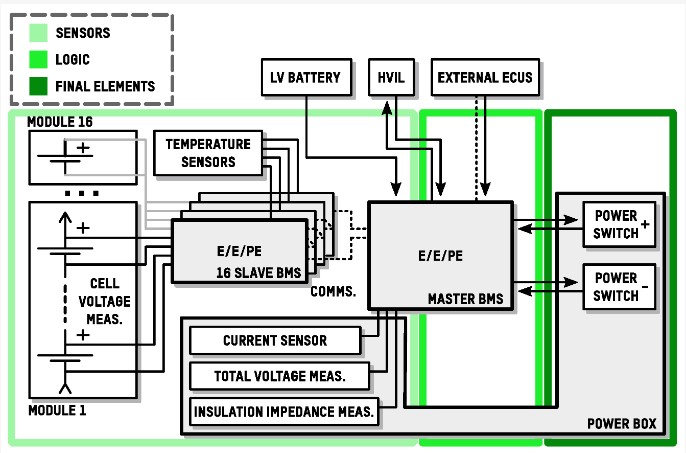

🔴 Battery State Monitoring

✅Real-Time Monitoring: Implement sensors to monitor voltage, current, temperature, and state of charge (SOC).

✅Redundant Systems: Ensure redundant monitoring to detect sensor failures.

✅Diagnostics: Provide real-time diagnostics for early fault detection.

🟢 Cell Balancing and Management

✅Balancing Techniques: Implement active/passive cell balancing to maintain uniformity.

✅Voltage Monitoring: Continuously monitor cell voltages to detect imbalances.

✅Thermal Management: Ensure effective thermal management to prevent overheating.

🟡 Overcharge and Overdischarge Protection

✅Voltage/Current Limits: Set precise limits to prevent overcharge and overdischarge.

✅Cutoff Mechanisms: Implement mechanisms to disconnect the battery if limits are exceeded.

✅Alarms and Notifications: Provide alerts for abnormal conditions.

🔵 Short Circuit and Overcurrent Protection

✅Fast-Acting Fuses: Use fuses and circuit breakers to protect against short circuits.

✅Current Sensing: Integrate current sensing and limiting features.

✅Fault Detection: Provide mechanisms for real-time fault detection and isolation.

🔴 Thermal Management

✅Cooling/Heating Systems: Implement systems to manage battery temperature.

✅Temperature Monitoring: Monitor temperature across cells and modules.

✅Thermal Runaway Detection: Provide detection and mitigation strategies.

🟢 Communication and Data Integrity

✅Robust Protocols: Use reliable communication protocols (e.g., CAN, LIN).

✅Error Detection: Implement error detection and correction mechanisms.

✅Data Logging: Ensure traceability for diagnostic purposes.

🟡 Functional Safety Management

✅Safety Culture: Foster a safety culture emphasizing functional safety at all levels.

✅Compliance: Ensure adherence to standards (e.g., ISO 26262, IEC 61508).

✅Safety Audits: Conduct regular audits and reviews.

🔵 Verification and Validation (V&V)

✅System Testing: Perform extensive testing, including Hardware-in-the-Loop (HIL) and Software-in-the-Loop (SIL) simulations.

✅Fault Injection Testing: Simulate faults to verify fault tolerance.

✅End-to-End Validation: Validate safety mechanisms comprehensively.

🔴 Continuous Monitoring and Updates

✅Safety Performance: Implement continuous monitoring of safety performance.

✅Software Updates: Provide regular updates and patches.

✅Periodic Assessments: Conduct regular safety assessments and improvements.

At Xenban we help companies to define, deploy and implement functional safety requirements.

Please visit www.xenban.com to know about products and services.